Table of Contents

P1K31FR30-001 - 3 axis bridge saw: User Manual

PS Bernard sistemare la tabella a “10.2.3.1.2. POCKETING - Parametri lavorazione “Tasca””

Mi manca da

- rimuovere le immagini dei zeri profili

- aggiornare elenco allarmi (ma spetto versione definitiva)

- aggiornare elenco warnings

|

|||

| Document | P1K31FR30-001 | ||

|---|---|---|---|

| Description | User manual | ||

| Drawn up | Riccardo Furlato | ||

| Approved | Draft | ||

| Link: | http://www.qem.eu/doku/doku.php/en/strumenti/qmoveplus/j1k31/mdu_p1k31fr30-001/funzionamento | ||

| Languages | English | ||

| Release | Description | Notes | Date |

| 01 | New Manual | 26/05/14 | |

All rights reserved on this manual. No part of this document can be copied or reproduced in any form without prior written authorisation. QEM does not insure or guarantee its contents and explicitly declines all liability related to the guarantee of its suitability for any purpose. The information in this document can be changed without notice. QEM shall not be held liable for any error or omission in this document. QEM® is a registered trademark.Microsoft® and MS-DOS® are registered trademarks and Windows® is a trademark of Microsoft Corporation.

Table of Contents

1. General Characteristics

Description

The P1K31FR30 - 001 software can be installed on the Qmove+ J1-K31-FR30, J1-P31, J1-P51, J1P71 hardware and is designed to control a bridge saw with 3 to 5 axes, for marble and granite. The salient features of the P1K31FR30 - 001 are described below.

Axes

-

Axes X, Y, Z controlled by PID on space (brushless motors with servo drives and brushless motors).

-

Axis W for the table rotation is manually controlled, with the operator entering the position on the controller

-

Axis H for the disk inclination is manually controlled, with the operator entering the angle on the controller

Optional

-

Axis W for the table rotation, with positioning accounting for inertia (asynchronous motor and V/F inverter) without interpolation.

-

Axis H for the disk inclination, with positioning accounting for inertia (asynchronous motor and V/F inverter) without interpolation.

Work Processes

-

Semiautomatic functions for positioning the axes and for single cuts.

-

Multiple cuts for block and slab cutting, with table rotation (W) for tile cutting.

-

Straight profiling with horizontal or vertical disk.

-

Step cutting with inclined disk (on machines that have disk inclination).

-

Straight profile finishing, using the face of the disk (interpolation of YZ).

Drawing

-

Profile programming by a miniCAD, embedded on the controller.

-

Import of profiles, saved on DXF file, by the “Profile Importer” conversion software (optional).

Work modes

-

Repeat the programmed shape.

-

Set the precision of the finishing.

-

Modify the speed of disk motion during the work cycle.

-

Compensation of the disk thickness and the disk diameter

Accessory functions, messages and alarms

-

Select the language

-

View the profile and the disk position, during the work cycle.

-

Diagnostics of the inputs and the outputs.

-

Backup and restore of the data on non volativle memory (FLASH EPROM).

-

Messagges for active faults, to assist troubleshooting.

-

Help Messagges.

-

Modbus interface for reading the absorbed current of the disk.

Optional Features (some not documented in this manual)

-

Profiles made with rotating table (similar to a vertical lathe).

-

Profiling with horizontal disk or vertical disk (XZ or XY interpolation).

-

Copying by photocell from a cardboard shape or black drawing on a whiteboard.

-

ISO manager with G code interpreter

Modbus Interface

-

The USER serial port can create a MODBUS RTU (RS485) network, for reading the disk rpm.

-

Serial port connection for a magnetic rule, for reading the absolute position of the axis.

1.1 Typical work results

2. Hardware J1-K31-FR30

2.1 Function Keys and LEDs

2.2 Symbols and keys

3. STARTUP

| START |  | OR  to bypass |

|

||

| HOMING |  | OR  to bypass |

| ALWAYS run Homing before going to MANUAL. Homing not OK limits machine operation. |

|

|---|---|---|

|

||

| MAIN MENU |  | |

4. Main Menu

5. Homing

5.1 Homing Procedure

-

external Machine Start button

external Machine Start button

-

The Delta Error is next to each Axis

6. Machine Data

7. Manual/Semiautomatic

|  |

|

| SET TARGET POSITION 9999 mm | - - -  | Auto-set ZERO position  |

|  | Disk Correction  OFF OFF  ON ON |

|  | Z jog   |

Default Z min  Auto-set Z min  |

||

|  | |

|  | |

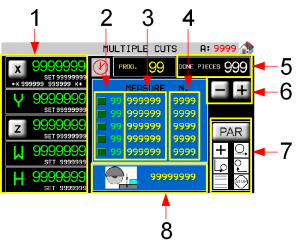

8. Multiple Cuts

8.0.1 No Rotating Table

8.0.2 Rotating Table

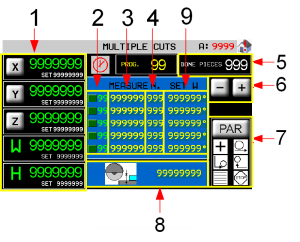

| 1 Target count and position 2 Work step now 3 Cut width (Y) 4 Number of cuts to make 5 Cutting depth (Z) 6 Piece counter 7 Scroll work program list 8 Work Parameters 9 Table Rotation (W) |

|

8.0.3 Axis parameters

8.0.4 Work Parameters

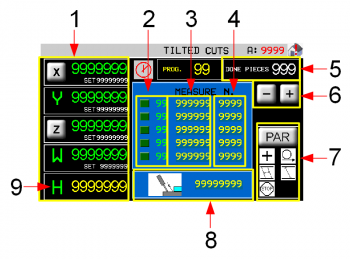

9. Tilted Cuts

9.0.1 Work Parameters

10. Programs

10.0.1 Program List Filters

Using the program's list filters is possible to get quickly the desired program, rather than scroll entire available list. The system permit two type of filtering which can be combined each other:

Using the program's list filters is possible to get quickly the desired program, rather than scroll entire available list. The system permit two type of filtering which can be combined each other:

-

Filter on program description

-

Filter on program type

Warn that “Type” mean:

| Type | Description |

|---|---|

| 0 | Show any program |

| 1 | Show only tagli sagomati/profilatura programs |

| 2 | Show only fresatura programs |

| 3 | Show only taglio poligoni programs |

10.1 PROFILES

10.1.1 PROFILE - CAD

Profiles with straight cuts

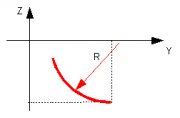

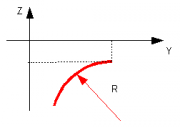

Draw a profile on the Y-Z plane

Never draw profiles on the other planes.

Profiles with curved cuts

1. Draw a profile on the usual Y-Z plane

2. Draw the curved cut

To change plane touch the

10.1.2 PROFILES - CAM

10.2 TOPS

10.2.1 TOPS - CAD

| Object tools | |

Add new object Add new object |  Delete all objects Delete all objects |  Delete object Delete object |

Copy an object Copy an object |    Move an object Move an object |    Rotate an object Rotate an object |

Resize an object Resize an object |   Mirror copy an object Mirror copy an object |   Draw a Parallel edge Draw a Parallel edge |

10.2.1.1 CAD Tools

10.2.2 DISK CUT - CAM

10.2.3 MILL CUT - CAM

10.2.3.1 TOPS - CAM Program

|  | Symbols on Objects |

The selected line is red  |

||

3 POINT ARC  |

||

|

| Scroll and Select from CAM list | |||||||

|---|---|---|---|---|---|---|---|

| | Add a CAM | | Delete a CAM | | CAM properties | |

| | Fit to screen | | | ||||

| Set the CAM | |||||||

| | Work OK CAM In Program | | Work OFF CAM Not in Program | | CAD object modified | |

10.2.3.1.1 CORE DRILL RECESSING

L'area interna di una geometria chiusa viene svuotata tramite foratura. Tale lavorazione calcola la posizione dei fori secondo una modalità impostata con i seguenti parametri.

10.2.3.1.2 MILL RECESSING

10.2.3.1.3 3D RECESSING

| 3D Recessing applied to a rectangle | ||

|---|---|---|

| 1 | Depth at center |

| 2 | Outside radius | |

| 3 | Inside radius | |

| 4 | Drain radius | |

| 5 | Closed object | |

| 6 | Depth at edge | |

| 7 | Tool path | |

11. WORK PROGRAMS

11.1 Run a Program

11.1.1 Work Program type 0 (Profili dritti)

| tasto marmo/granito |  |  STOP STOP  |  |

| Work Parameters | see Work Program  |

MACHINE START.

MACHINE START.

| Nel dare start al ciclo automatico verrà richiesta un'operazione di azzeramento delle quote degli assi. |

|---|

GRANDE

11.1.2 Work Program type 0 (Profili sagomati)

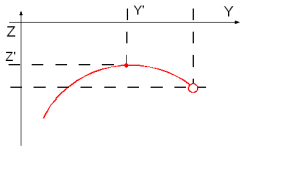

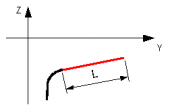

I tagli vengono realizzati in successione con un'unica passata (marmo) oppure ad incrementi successivi (granito) in accordo con i parametri impostati in precedenza. La successione dei tagli compone la sgrossatura del profilo. I tagli vengono eseguiti partendo dalla quota X autoappresa minima aggiungendo due tratti orizzontali lunghi come il raggio della lama, prima e dopo il profilo disegnato.

Si potranno presentare quindi due casi:

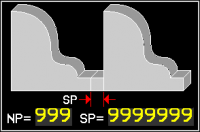

In questo caso la larghezza del profilo sommato al diametro della lama è maggiore della distanza tra le due quote di X autoapprese. Come si vede dalla figura, il taglio parte alla quota minima autoappresa e viene eseguito completamente fino a superare la quota X massima autoappresa.

In questo caso la larghezza del profilo sommato al diametro della lama è minore della distanza tra le due quote di X autoapprese. Come si vede dalla figura, il taglio parte alla quota minima autoappresa ,mentre il tratto orizzontale finale viene prolungato fino a portare il centro della lama sulla quota X autoappresa massima.

Il processo di finitura non è previsto per le lavorazioni di taglio curvilineo.

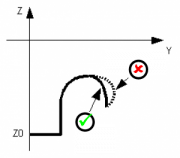

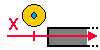

Questa schermata spiega che la lama deve essere portata a sfioro del blocco (come rappresentato), prima di dare l' OK per l'azzeramento delle quote degli assi.

11.1.3 Work Program type 1 or 2 (Profili sagomati)

Nella pagina di esecuzione 2D è possibile lanciare l'esecuzione di un programma 2D. Nella lista di lavorazioni sono evidenziate a gruppi di 5 in un menu scorrevole le singole operazioni che compongono il programma. Durante l'esecuzione verrò visualizzata l'esecuzione della lavorazione in maniera simile a quanto ottenuto in fase di programmazione.

| Nel dare start al ciclo automatico verrà richiesta un'operazione di azzeramento delle quote degli assi. |

|---|

11.1.4 TOPS Work Program

12. ISO G codes

|  |

|

|  |

|

| Optional accessory requiring QEM Isomanager (see specific manual  insert link ) insert link ) |

|

| When using an SD card rename the .hex file with a number (0 ~ 999999). (file name: 1.hex, 2.hex…) | |

Program State

| Run Mode | 1: read from SD card read file from a Memory card 2: read from PC read file from the PC connection 3: save on SD card only save file from PC to SD card |

| SD card program number | the .hex file number in the SD card. |

| Read status | the percentage progress of reading the file on SD card. |

| Block Executed | ISO instructions executed. |

| G code of actual line num. | the actual ISO instruction number. |

| G code actual line | the actual ISO instruction. |

Program settings

13. Alarms

Alarms block the machine operation.

| Alarm | Cause | Solution |

|---|---|---|

| Emergency | Manual emergency stop | - |

| Y limit switch backward | Y-axis at minimum LS | - |

| Y limit switch forward | Y-axis at maximum LS | - |

| Z limit switch backward | Z-axis at minimum LS | - |

| Z limit switch forward | Z-axis at maximum LS | - |

| X limit switch backward | X-axis at minimum LS | - |

| X limit switch forward | X-axis at maximum LS | - |

| H limit switch backward | H-axis at minimum LS | - |

| H limit switch forward | H-axis at maximum LS | - |

| Disk not running | Disk must be running in automatic cyle | - |

| Water pressure | No cooling water | The water valve shut |

| Disk motor overcurrent | The disk motor current absorption is over the threshold | - |

| Z Following error | The axis follow error is over the maximum threshold | - |

| Y Following error | - | |

| X Following error | - | |

| Interpolation fault | Error during axis interpolation | One axis over the maximum position |

| Thermic fault | Overload of drivers tripped | - |

| Driver is fault | Fault in one of the axis drivers | - |

| X encoder fault | Axis encoder malfunctioning | - |

| Y encoder fault | - | |

| Z encoder fault | - | |

| W sensor missing | Low table sensor may be disconnected | - |

| Y Axis out of tolerance | Axis positioning out of tolerance | Check axis setup parameters |

| Z Axis out of tolerance | ||

| W Axis out of tolerance | ||

| H Axis out of tolerance | ||

| CAN module - data error | CAN module error | Check CAN comunication or cable |

| CAN module - no comunication | CAN module not responding | |

| SD CARD not present | Error in SD card upload/download | Check the MMC/SD support, check the correct procedure |

| MMC/SD error update | ||

| MMC/SD file not open | ||

| MMC/SD file not create | ||

| MMC/SD error write | ||

| MMC/SD error seek | ||

| MMC/SD error read | ||

| MMC/SD error read seek | ||

| MMC/SD error read format | ||

| MMC/SD error record | ||

| MMC/SD error delete | ||

| MMC/SD error max retry | ||

| MMC/SD undefined error | ||

| INT: motion mode not defined | Interpolation interpreter error | - |

| INT: exact path mode not supported | ||

| INT: invalid istruction | ||

| INT: invalid version | ||

| INT: invalid release | ||

| INT: spindle management | ||

| INT: change tool management | ||

| Mechanical components activation error | Interpolation execution error | |

| INTERP writing error | ||

| INTERP starting error |

13.1 Alarm History

13.2 Warning Messages

Messages do not block the machine operation.

| Messagge | Cause | Solution |

|---|---|---|

PLEASE WAIT…  | Data being processed | - |

| WAITING FOR POWER SYSTEM |  | Check the emergency button is not pressed |

PATH  ERROR ERROR | There is an error in the path settings,  before the process. before the process. | The path may be too long |

| DISK TILT ERROR | The disk or tool tilt is not correct for the work cycle | Correct the disk or tool tilt |

| WORK DONE | Automatic cycle is completed successfully | - |

| X POSITION NOT OK | X position is incorrent | X position is outside the auto-set min-max positions |

| RUN HOMING | The Homing is not OK | Run the homing procedure |

14. Diagnostics

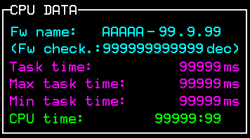

14.1 CPU DATA

14.2 Inputs

14.3 Outputs

14.4 Encoder Counts

14.5 Analog outputs

14.6 Controllo dei finecorsa

Controllo dei finecorsa hardware

Controllo dei finecorsa 0° - 90° del disco

| Disk auto speed table (password)  Va su installazione non qui Va su installazione non qui |

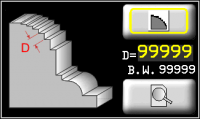

Tool compensation limits

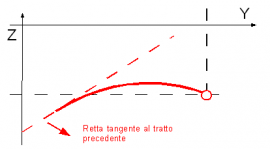

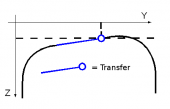

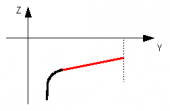

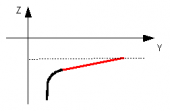

Una volta impostato il diametro dell'utensile nella apposita pagina della lavorazione 2D, viene proposto all'operatore il percorso utensile disegnato con un tratto blu. L'operatore deve eseguire un controllo visivo della correttezza del percorso utensile.

Tale controllo è necessario per verificare la correttezza del percorso nel caso in cui si siano verificati i casi limite di seguito elencati:

Percorso utensile che si chiude su se stesso:

This does not cause a tool compensation error.

clockwise

clockwise

anticlockwise

anticlockwise