Indice

P1P20FH20 - 001 : User Manual

|

|||

| Document | MDI_P1P20FH20-001 | ||

|---|---|---|---|

| Description | User Manual | ||

| Drawn up by | Michele Sandri | ||

| Approved by | Gabriele Bazzi | ||

| Link | http://www.qem.eu/doku/doku.php/en/strumenti/qmoveplus/j1p20/p1p20fh20-001/mdo_p1p20fh20-001 | ||

| http://www.qem.eu/doku/doku.php/strumenti/qmoveplus/j1p20/mimj1p20fx | |||

| Language | English | ||

| Document Release | Description | Notes | Date |

| 01 | New manual | 07/07/2014 | |

All rights reserved on this manual. No part of this document can be copied or reproduced in any form without prior written authorisation. QEM does not insure or guarantee its contents and explicitly declines all liability related to the guarantee of its suitability for any purpose. The information in this document can be changed without notice. QEM shall not be held liable for any error or omission in this document. QEM® is a registered trademark.Microsoft® and MS-DOS® are registered trademarks and Windows® is a trademark of Microsoft Corporation.

Indice

-

1. Release3. Descrizione

-

3.1. Simbologia e Tasti4. Messa in funzione

-

4.11. Tarature5. Diagnostica7. Programmi di lavoro

-

7.1. Modifica programma di lavoro8. Funzioni generiche

-

8.1. Manuale Automatico

1. Descrizione

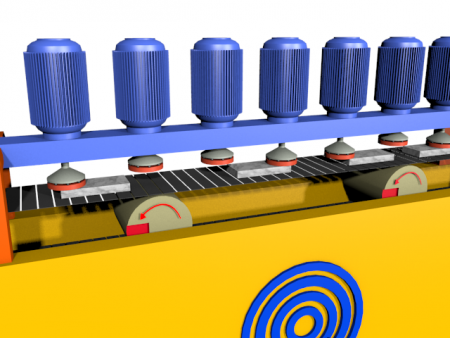

Il software P1P20FH20 - 001, installato nell'hardware Qmove J1-P20-FH20, realizza l'automazione di macchine levigatrici/levigabordi .

Caratteristiche principali

-

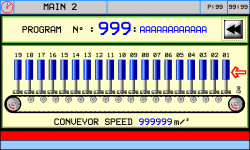

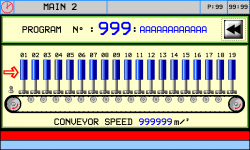

lo strumento comanda 19 teste di lavoro

-

controlla l'avviamento sequenziale dei motori (per limitare l'eccessivo richiesta di corrente )

-

gestisce l'eventuale spostamento del ponte

-

per ogni testa di lavorazione è possibile impostare gli anticipi e i ritardi di lavorazione, sia all'inizio, sia alla fine del pezzo

-

I comandi di salita/discesa delle teste di levigatura, vengono calcolati automaticamente al variare della velocità del nastro trasportatore.

-

lo strumento conta i metri lavorati ed è in grado di lavorare fino a 30 pezzi presenti contemporaneamente in macchina.

Altre Caratteristiche

-

HMI con touchscreen

-

Tasti funzione

-

Programmi di lavoro

-

Messaggi di allarme

-

Messaggi di warning

-

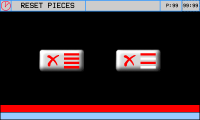

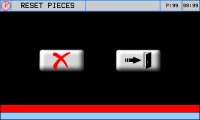

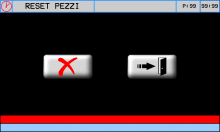

Reset dei pezzi difettosi

-

Reset di tutti i pezzi in lavorazione

-

Compensazione dell'offset del finecorsa di presenza pezzo

-

Modo di lavorazione delle teste

-

Levigatura

-

Fresatura

-

Molatura

-

Spazzolatura

-

Getto d'acqua

Opzioni e caratteristiche di possibile futura implementazione

-

Con l'installazione dei moduli RMC1XX sarà possibile automatizzare 2 o 4 calibratori

-

Con l'installazione dei moduli RMC1YY sarà possibile leggere la corrente di ogni testa

-

E' possibile dotare lo strumento del software necessario per realizzare delle lavorazioni di bocciardatura

-

E' possibile dotare lo strumento di funzionalità software di abilitazione/disabilitazione di ogni singola testa

-

E' possibile dotare lo strumento di porta Etnernet, che consente di trasmettere i dati della macchina agli uffici di programmazione della produzione .

-

Risparmio energetico : accensione dei motori solo durante la lavorazione

Nota : in questo caso si dovrà utilizzare un modulo di espansione degli I/O

Note Se il cliente è interessato a queste opzioni e caratteristiche, oppure altre di Sua scelta, contattare l'Ufficio Commerciale della QEM ( info@qem.it )

2. Hardware J1-P20-FH20

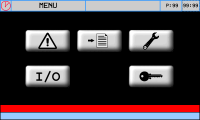

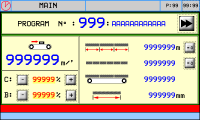

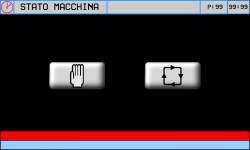

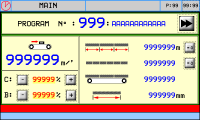

MAIN MENU

RESERVED SETUP (enter password)

WORK PROGRAMS

RESET ALL SLABS

RESET SELECTED SLABS

ALARMS

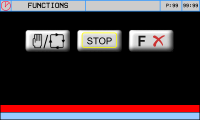

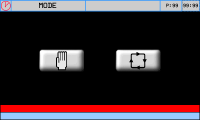

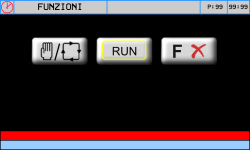

ESC TO PREVIOUS SCREEN 2.1 Standard Symbols & Buttons

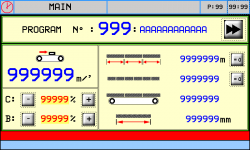

3. Main Screen

Right IN

Right INTop Bar (grey)

- Machine State

- Page name

- Page number

- Time

Bottom Bars

- Alarms (red)

- Warnings (light blue) Left IN

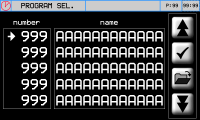

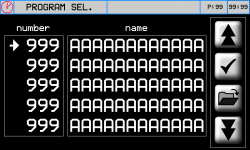

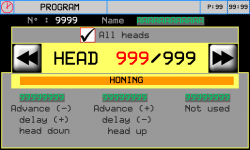

Left IN4. Work Programs

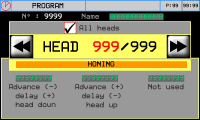

Automatic Program:

-

To change the program settings, press each box and enter the settings.

-

Press ALL HEADS to copy the HEAD 1 settings to all heads

-

Set the work parameters

-

press F7 to quit

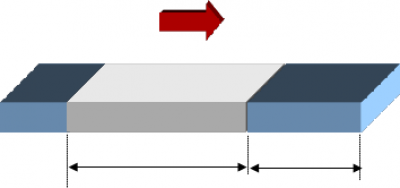

Advance (-)

delay (+) head downAt start of slab set Advance with (+) entry and Delay with (-) entry Advance (+)

delay (-) head downAt end of slab set Advance with (-) entry and Delay with (+) entry 4.0.1 Polishing parameters

All default work parameters are set to 0.

Parameter Unit measure Range Description Advance(-)/Delay(+) head down mm 0 ~ 99999.0

Advance or delay distancehead down at start of slab . Advance(+)/Delay(-)head up mm 0 ~ 99999.0 head up at end of slab . .

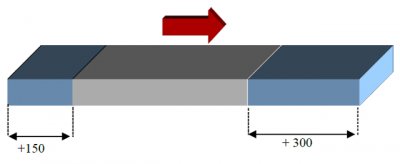

4.0.2 Parametri fresatrice

Nome parametro Unità di misura Range Descrizione Start slab distance / grinding mm 0 ~ 99999.0 Distance between slab start and start grinding End slab distance / grinding mm 0 ~ 99999.0 Distance between slab end and stop grinding Grinding length mm 0 ~ 99999.0 Grinding length

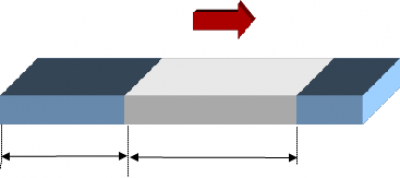

If one distance is greater than zero, the other is automatically set to -1 (disable parameter) Fresatura con riferimento da inizio pezzo Fresatura con riferimento dalla fine del pezzo

Spazio fresato

Parametro:

lunghezza di fresaturaSpazio non lavorato

Parametro:

distanza inizio pezzoSpazio non lavorato

Parametro:

distanza fine pezzoSpazio fresato

Parametro:

lunghezza di fresatura4.0.3 Parametri mola

Nome parametro Unità di misura Range Descrizione Metri lineari lavorati mm 0 ÷ 99999.0 Spazio oltre il quale viene attivata la compensazione usura mola . Tempo attivazione testa sec. 0 ÷ 99999.0 Tempo di attivazione, la testa fa uno spazio in avanti per compensare l'usura della mola . 4.0.4 Brush Parameters

The brush parameters are similar to honing above.

4.0.5 Water Spray Parameters

The brush parameters are similar to honing above.

5. Work mode

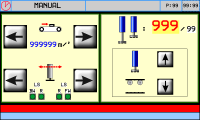

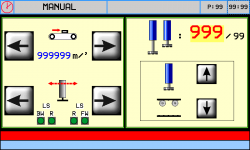

5.1 Manual mode

5.2 Automatic mode

The machine works in automatic by default.

To go from Manual to Automatic always select it as the work mode

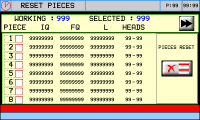

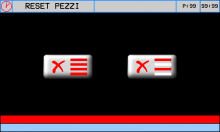

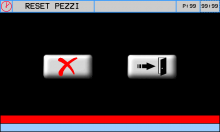

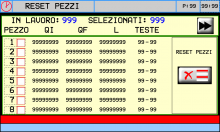

6. Cancel Slabs

Cancel all slabs

Cancel selected slabs

Parameter Description Working Slabs in the machine Selected Total of selected slabs QI Distance between slab IN sensor (I09) and start of slab QF Distance between slab IN sensor (I09) and end of slab L Slab length Head <> Signals that the slab is between two heads 7. Alarms

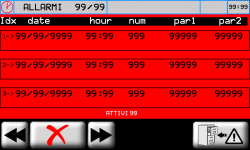

7.1 Alarm list

.

Message Cause Input Emergency pressed Check the emergency button and line I01 Inverter fault Control the inverter I12 Belt encoder fault Control the belt encoder (Acive only with MP-03 > 2). Overload cutouts Check the overload cutouts I06 Enclosures Check the enclosures I07 No air Check the air pressure switch I08

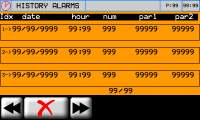

the Belt encoder fault alarm trips automatically if the belt moves less 2 u.m. in 5 seconds (less than 60 mm/min) 7.2 Alarm history

8. Warnings

Message Description Too many slabs in the machine There are more than 30 slabs in the machine Waiting for power system… Waiting for the power system to startup (MP-08 enabled)(I04 = ON ) Going to change abrasive position… The beam has been commanded to move to change abrasive Power system disabled Power system disabled (I04 = OFF). Caution Motors off Belt start attempted with motors off -