DEVICE OOPOS2

1. Introduction

-

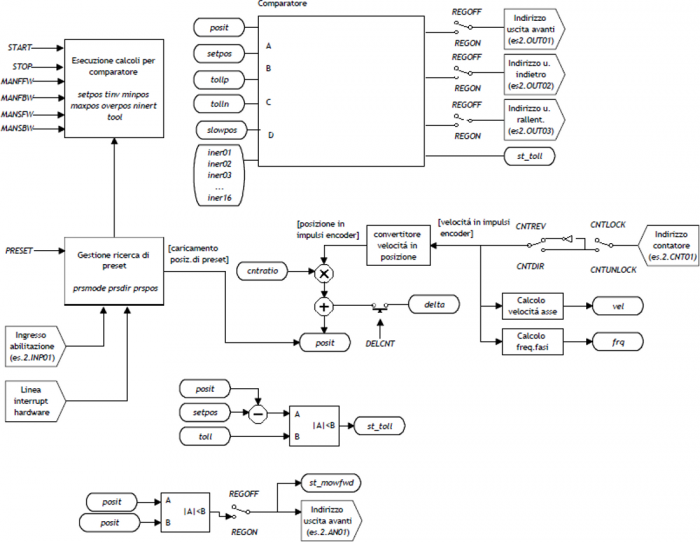

The OOPOS2 device can control the location of an axis moved basically from digital controls of forward, backward and slow; the location of the axis is acquired via a bi-directional transducer.

-

The movement commands can be sent directly to the motor in AC via contactors, or be sent to an inverter.

-

The OOPOS2 device includes all functions necessary for the implementation of ON/OFF placements, in addition to special functions such as automatic recalculation of inertia, the mechanical backlash recovery management, managing the slowdown is proportional to the speed and a complete search of presets to synchronize the actual position of the axis with the internal value of the device.

1.1 Installation

1.1.1 DEVICE DECLARATION IN THE CONFIGURATION FILE (.CNF)

In the configuration file (.CNF), the BUS section must be declared so that you have the hardware resources required for the implementation of the OOPOS2 device.

There must be at least a bi-directional meter. The device can also use an interrupt input and a line for preset search functions.

In the INTDEVICE section of the .CNF file must be add the following definition:

;--------------------------------- ; Internal device declaration ;--------------------------------- INTDEVICE <device name> OOPOS2 TCamp IQCTL ILine IAZero OutAva OutInd OutDir OutMov OutRal OutFre

| It is necessary that each definition are present on the same line. In case you do not want to assign a resource, for example OutFre, You must always enter in the appropriate field the string X.X. |

|---|

where:

| <nome device> | The name assigned to the device. |

| OOPOS2 | Keyword that identifies the on/off positioner device. |

| TCamp | Sampling time device (1÷255 ms). |

| IQCTL | Bidirectional incremental counter address. |

| ILine | Interrupt line dedicated to the zero pulse. |

| IAZero | Input to enable the capture of zero-pulse. |

| OutAva | Address of output used as forward output. |

| OutInd | Address of output used as backward output. |

| OutDir | Address of output used as direction output. |

| OutMov | Address of output used as motion output. |

| OutRal | Address of output used as slowdown output. |

| OutFre | Address of output used as brake output. |

1.1.1.1 Example

;-------------------------------- ; Internale device declaration ;-------------------------------- INTDEVICE Axis OOPOS2 0004 2.CNT01 1 2.IN01 2.OUT01 2.OUT02 X.X X.X 2.OUT3 X.X

1.2 GETTING STARTED ON ON/OFF POSITIONING

The digital outputs for managing the placement are enable/disable depending on the position of the axis (counter), appropriately controlled by the device depending on the parameterization.

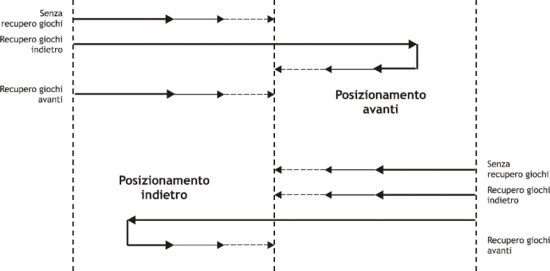

The ON/OFF positioning can executed in both directions (forward/backward) with the possibility of retrieving games, for deletion of any mechanical backlash.

1.2.1 Retrieving backlash

The accuracy with which was built the mechanics is critical to the outcome of the placements. It is impossible to find, on the placements, the precision of the motion of bodies if the moving parts have loose backlash of the tenth. Also on placements of vertical axes very heavy (for example a press or vertical cutter), the inertia of movement upwards is less than the inertia of movement down.

In these and other situations implementation of recovery backlash in positioning significantly improves accuracy.

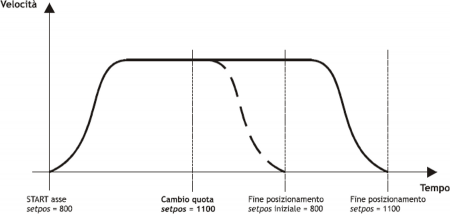

| The positioning is always concluded in the same direction. For example, whereas placements with recovery forward backlash (see Picture 1), for both forward and reverse positioning, the movement of the axle ends always moving from left to right (forward). |

|---|

| Picture 1: positioning diagram with recovery backlash. |

|

1.2.2 FORWARD POSITIONING WITHOUT RECOVERY BACKLASH

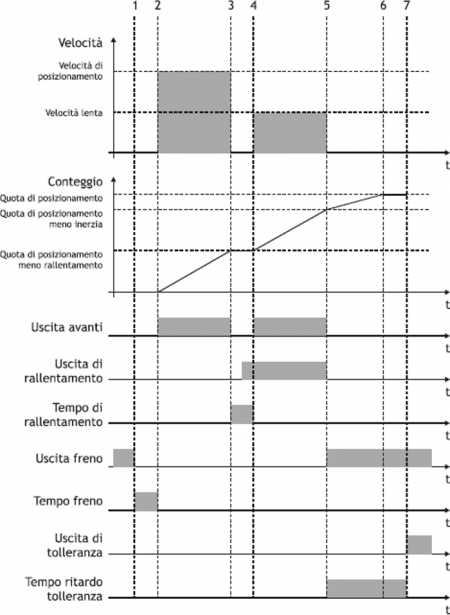

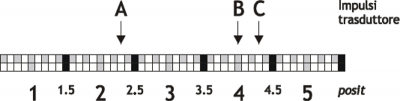

In the Picture 2 Describes the various stages of a ON/OFF placement forward without the implementation of recovery backlash.

The excitement of moving outputs (in this casa the forward output) moving the axis; increasing the count acquired and the appropriate device parameters involve the activation of several resignations to motion management, up to the end of placement and the activation of tolerance output (positioning report concluded correctly).

| Picture 2: forward positioning without the recovery backlash. |

|

1.2.2.1 Initial conditions

-

The axis is stopped (st_still = 1).

-

The count is reset to zero (posit = 0).

-

All outputs are disable (with the exception of brake output).

-

You have set both the share placement (setpos) that the slowdown quota (slowpos).

1.2.2.2 Phase 1

-

The OOPOS3 device receives the command of START positioning.

-

Brake output disabled (st_brake = 0).

-

The advance brake output timer is set to the value defined in the tbrake parameter.

1.2.2.3 Phase 2

-

Terminates the advance brake output timer.

-

It's enabled the forward output (st_movfwd = 1).

-

The axis begins the movement (vel) and the counter (posit) increases.

-

After an acceleration ramp (defined from mechanical inertia or in any acceleration values set in the inverter), axis speed is constant.

1.2.2.4 Phase 3

-

Positioning reaches the deceleration range (setpos - slowpos).

-

The forward output is disable (st_movfwd = 0).

-

The slowdown timer is set to the value defined by the parameter slowdly.

-

When the timer of slowdown is half the value set, activates the slowdown output (st_movslow = 1): This is to avoid problems with special switches-mechanical devices.

1.2.2.5 Phase 4

-

Ends the slowdown timer.

-

Is enabled the forward output (st_movfwd = 1).

-

The axis moving with slow speed.

1.2.2.6 Phase 5

-

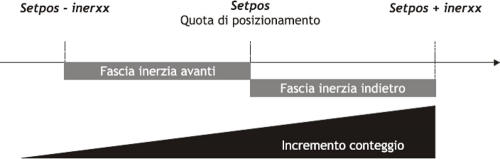

The placement reached the inertial range (setpos - iner[ninert]).

-

The forward (st_movfwd = 0) and slowdown (st_movslow = 0) outputs are disabled.

-

The delay timer tolerance is set to the toldly value and start counting.

-

The axis keeps moving because of its inertia (variable according to its weight, speed, friction).

1.2.2.7 Phase 6

-

The axis stops.

-

It is important that the axle ends the movement before the end of the timer to delay tolerance.

1.2.2.8 Phase 7

-

Terminates the delay tolerance timer.

-

Brake output is enabled (st_brake = 1).

-

If enabled, runs the recalculation of inertia.

-

If the placement ends in tolerance, is enable the out of tolerance (st_toll =1).

1.2.3 FORWARD POSITIONING WITH RECOVERY BACKLASH IN BACKWARD DIRECTION

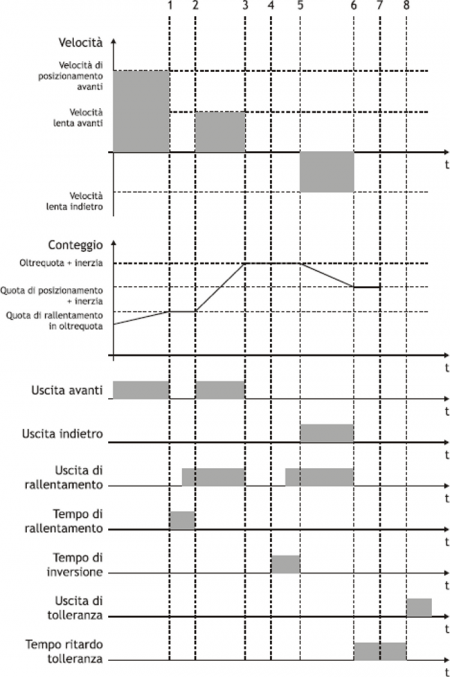

In the Picture 3 describes the various stages of a ON/OFF forward placement with the implementation of recovery backlash in backward direction.

The activation of (forward / backward) outputs moving the axis; the increasing of the count acquired and the appropriate device parameters involve the activation of other outputs to the motion management, up to the end of placement and activation of the output of tolerance (positioning report concluded correctly).

| Picture 3: forward positioning with backward recovery backlash. |

|

1.2.3.1 Premise

For complete understanding of this description you should have read the previous paragraph (FORWARD POSITIONING WITHOUT RECOVERY BACKLASH).

1.2.3.2 Initial conditions

-

The axis moves at the speed of positioning.

-

Count greater than zero.

-

All disable outputs except the forward output.

1.2.3.3 Phase 1

-

The count reaches the deceleration range for recovery overquota backlash (setpos + overpos - slowpos).

-

The forward output is disabled (st_movfwd = 0).

-

The slowdown is set to the value of the slowdly parameter.

1.2.3.4 Phase 2

-

Terminates the timer advance unlock brake.

-

It's enabled the forward output (st_movfwd = 1).

1.2.3.5 Phase 3

-

Terminates the slowdown timer.

-

It's enabled the forward output (st_movfwd = 1).

-

The axis moves at low speed.

1.2.3.6 Phase 4

-

Positioning reaches the inertial range (setpos + overpos + iner[ninert]).

-

The forward (st_movfwd = 0) and slodown (st_movslow = 0) outputs is disabled.

-

The reverse timer is set to the value of tinv.

1.2.3.7 Phase 5

-

Terminates the reverse timer.

-

The placement resumes in the backward direction.

1.2.3.8 Phases 6÷8

-

Normal positioning phases as described above.

1.3 Operation

1.3.1 HARDWARE CONNECTION

The OOPOS3 device needs some necessary hardware resources, as a bidirectional counter input (CNTxx) and the digital outputs.

1.3.2 CHECK THE OPERATION OF THE COUNTER RESOURCE

The following procedure is used to test the counter input.

-

Initialize the device axis with INIT command.

INIT Axis -

Checking if the st_init state activation.

WAIT Axis:st_init -

Enter the value 100000 in the cntratio parameter.

Axis:cntratio = 100000 -

Reset the value of posit parameter.

Axis:posit = 0 -

Move forward one revolution axis turning the encoder: verify that the value of the Axis:posit variable it's positive and matches the number of pulses/Rev encoder.

-

If the Axis:posit value is negative, swap the encoder phases.

If the Axis:posit value remains to zero, check the electrical connections.

1.3.3 CHECK THE OPERATION OF THE DIGITAL OUTPUTS

| Before moving the axis, check the proper operation of emergency equipment and protection. |

|---|

The following procedure is used to verify the operation of the digital outputs of forward, backward and slowdown moving the axis with the manual commands of the device.

To continue, verify that the Axis device is initialized and with the correct Asse:cntratio value.

-

Set the maximum value the software limits of the device in order to enable its movement. Insert the 999999 value in the maxpos parameter and the -999999 in the minpos parameter.

Axis:maxpos = 999999

Axis:minpos = -999999 -

Give the MANFFW command to active only the forward output..

MANFFW Axis -

To verify the correct execution of the command, check that the st_still state is to 0 and st_movfwd is to 1:

WAIT NOT Axis:st_still AND Axis:st_movfwd -

Check that the axis moves forward and that the count showed in

Axis:positit increments, then stop the movement with the STOP command.

STOP Axis -

If the forward output, for example is correspondent to the 2.OUT01 resource, don't enable, check the electrical connection.

-

Dare il comando MANFBW per eccitare la sola uscita d'Indietro.

MANFBW Axis -

To verify the correct execution of the command, check that the st_still state is to 0 and st_movbwd is to 1:

WAIT NOT Axis:st_still AND Axis:movbwd

1.4 Functions

1.4.1 Multi-axis management

In some applications you are prompted to place a large number of axes by moving a single axis at a time. The choice may be to install one drive which depending on the axis to be placed electrically connects the engine interested in positioning; the transducer is always bound to its axle.

The EPICPOS parameter allows you to control access to the DAC device using the REGON and REGOFF commands. In this way through the QCL application defines a set of device many axes to be placed; in the definition, all devices use the same resource DAC (IOutA).

Normally all devices must be in the st_regoff = 1 state so you will not have access to the DAC. Before you start positioning, with the REGON command, the device is brought to the st_regoff = 0 state. It's execute the placement and to the completion, the device is returned in the st_regoff = 1 state with REGOFF command. For no reason two devices simultaneously must be found in the st_regoff = 0 state.

When the device is placed in the regoff position, the analog output remains fixed at the last voltage value defined before the REGOFF command.

1.4.2 Change quota and count in motion

| Changing the quota is accepted only if the new position is reached with the use direction and if the axis is not already in slowdown phase for to reach the quota previously set. |

|---|

In some applications you are prompted to define the target quota during placement, depending to external events to the device. With this feature you can write in the setpos parameter even with current placements.

When positioning you can also change the value of the count posit. This function is usually used when a device must, under special conditions, continue a speed profile for a very long time, exceeds the time axis takes to reach the quota limit (maxpos or minpos).

-

Check that the axis moves back and that the count showed in

Axis:positdecreases, then stop the movement with the STOP command.

STOP Axis -

If the backward output Se l'uscita di Indietro, for example the resource

2.OUT02, don't enable, check the electrical connection. -

Give the MANSFW command to enable the forward and slowdown outputs.

MANSFW Axis -

To verify the correct execution of the command, check that the st_still state is to 0, st_movfwd is to 1 and st_movslow is to 1:

WAIT NOT Axis:st_still AND Axis:st_movfwd AND Axis:st_movslow -

Check that the axis from moving forward at a speed lower than the previous and that the count showed in

Axis:positis increments, then stop the movement with the STOP command.

STOP Axis -

If the slowdown output, corresponding to the

2.OUT03resource, does not turn on, check the electrical connection.

1.4.3 Axis resolution parameter setting

To Introduce the locating dimensions in desired unit (Um) You must multiply the pulses generated by the transducer for the multiplicative ratio (cntratio); this parameter must be between the values: 374 < cntratio < 400000.

Multiplicative coefficient calculation As an example, consider introducing dimensions in mm; the unit of measurement (Um) will be in mm.

If the space of 1000 mm is accomplished with 20000 pulses, the Axis:cntratio variable should be set to:

Axis:cntratio = Um x 100000 / pulse_numbers

that is:

Axis:cntratio = 1000 x 100000 / 20000 = 5000

Multiplicative value of 100000 adapt the result of dividing to the format in which is expressed the variable Axis:cntratio.

This is an integer number but expresses a value with a decimal point at the fifth significant digit. To write Axis:cntratio=100000 means setting a ratio Um/pulse_numbers equal to 1.00000.

1.4.3.1 Example

-

Enter the value 100000 in the cntratio parameter

Axis:cntratio = 100000 -

Reset the value of the posit parameter

Axis:posit = 0 -

Shift the axis of a specific space, for example 1000 mm., that call Sp.

-

Capture the value of the Axis:posit parameter

-

In Axis:cntratio introduce the integer value resulting from the formula:

Axis:cntratio = Sp * 100000 / Axis:posit

1.4.4 Basic settings

For work properly the OOPOS2 device, you must enter a few basic parameters.

-

Determining the software limits to be introduced in the maxpos and minpos parameters.

Axis:minpos = xxx(xxx = minimum axis value expressed in Um).

Axis:maxpos = yyy(yyy = maximum axis value expressed in Um). -

If you are using a two speed system, set the required space to the axis to switch from high speed to slow speed the at the enabled of the slowdown output; insert the data in the slowpos parameter.

Axis slowpos = zzz(zzz = slowdown axis value expressed in Um). -

Set the time for disable the output of movement when the shaft enters the deceleration range so that the slowdown output does not cause electrical failure or excitement; so that the output slowdown does not cause electrical failure or excitement;slowdly.

Axis:slowdly = ttt(ttt = slowdown time in s/100). -

Set the tolerance limits to be obtained when placing in the parameters tollp and tolln. As a first approach, introducing the higher values at precisions requests.

Axis:tollp = tpx(tpx = positive tolerance value expressed in Um/10).

Axis:tolln = tnx(tpn = negative tolerance value expressed in Um/10). -

Set the time axis inversion in the tinv parameter.

Axis:tinv = inversion time expressed in s/100 -

Consider a single inertia range for all axis; then, set the ninert parameter to “1”.

Axis:ninert = 1 -

Enable recalculation of inertia when the placement ends out of tolerance; then, set the inertmode parameter and “1”.

Axis:inertmode = 1 -

Set the time delay tolerance, considering the time it takes for the axis to decelerate to a stop; then, set thetoldly parameter.

Axis:toldly = tdly(tdly = activation time delay tolerance expressed in s/1000).

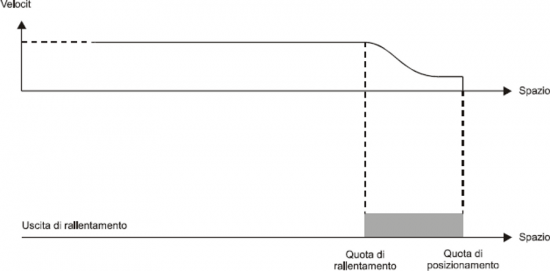

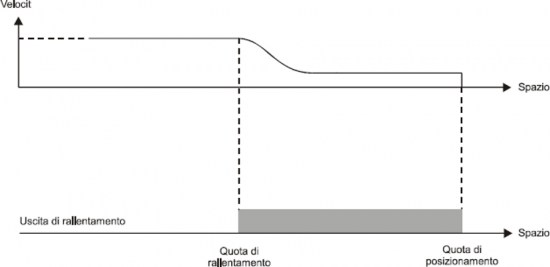

1.4.5 The slowdown

1.4.5.1 Introduction

In the ON/OFF placements the space of slowdown should be long enough to bring the axis at the slow speed (of end placement), which enter the inertial range and conclude your placement in tolerance. It is essential that the speed at the time of entry in the inertial range is always equal, so that inertia is repetitive and continuous recalculations are avoided that would cause an inaccuracy in positioning.

| Correct slowdown quota: before stopping the axis moves at low speed, facilitating the stop without compromising the execution time of positioning |

|---|

| Slowdown quota is too long: This allows the axis to end positioning by moving the slow speed, but is maintained for too much space, extending considerably the time of positioning. |

|---|

| Slowdown quota is too short: the axis approaches at the quota with a speed too high to allow the mechanical rapid stop; the succession of the system compromises the placement, stopping the axle out of the tolerance range set. |

|---|

In some cases the OOPOS3 device must manage the axis where positioning speed is variable. For this reason the OOPOS2 device has a system of automatic calculation of the slowdown quotaq, so the speed of end placement and the inertia value are repetitive, regardless of the speed of the axis and the value of inertia are repetitive, regardless of the speed of the axis..

The OOPOS2 device has two methods (selected by the slowtype parameter), to calculate the slowdown:

-

With slowtype = 1, the slowdown is calculated proportionately to the positioning speed.

-

With slowtype = 2, the slowdown is calculated according to the square of the positioning speed.

1.4.5.1.1 Setting of the speed variable

To calculate the slowdown value you need setting to acquire the axis speed.

The unit of speed is in function of the following variables:

-

unitvel

-

decpt

Unitvel parameter Defines if the speed values are expressed in Um at the minute (unitvel = 0) or in Um at the second (unitvel = 1).

Decpt parameter Whether to set the values of speed in multiples of the fundamental units Um. For example, if the fundamental unit of measure Um=mm, and unitvel=1 you get the speed indicator in the vel variable:

-

with decpt = 0 in mm/s

-

with decpt = 1 in cm/s

-

whit decpt = 2 in dm/s

-

whit decpt = 3 in m/s

1.4.5.1.2 Maximum speed calculating

Theoretical method

you have to apply the formula:

Speed = Frequency * ….

Pratical method It's based on the speed reading detected by the device in the vel parameter giving the drive a known voltage. If driving permits, provide the maximum working voltage axis and then read the value in the vel parameter; if you provided a lower voltage, the maximum speed will be proportional to the voltage supplied.

Enter the value of the maximum speed detected in maxvel parameter.

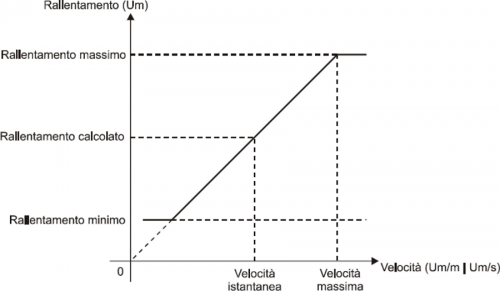

1.4.5.2 Proportional to the speed slowdown

The device calculates the slowdown based on the formula:

Slowdown = (Maximum slowdown x Speed)/Maximum speed

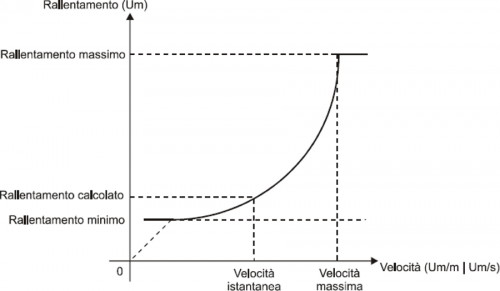

| The calculation of the slowdown, as evidenced by the chart, one of the two maxslow or minslow limits cannot exceed. |

|---|

where:

Maximum slowdown = corresponds to the maxslow variable.

Minimum slowdown = corresponds to the minslow variable.

Calculated slowdown = corresponds to the exeslow variable.

Maximum speed = corresponds to the maxvel variable.

Instantaneous speed = corresponds to the vel variable.

1.4.5.2.1 Proportional slowdown to the square of the speed

The device auto-calculates the slowdown based on the formula:

Slowdown = (Maximum slowdown x Speed2)/Maximum speed

where:

Maximum slowdown = corresponds to the maxslow variable.

Minimum slowdown = corresponds to the minslow variable.

Calculated slowdown = corresponds to the exeslow variable.

Maximim speed = corresponds to the maxvel variable.

Instantaneous speed = corresponds to the vel variable.

1.4.6 RECALCULATION OF INERTIA

The values of inertia can be introduced directly by the operator or automatically calculated from the device; the mode is chosen with setting the inertmode parameter.

The device manage the subdivision of the axis path (between the minpos and maxpos) in more same bands; the number of bands is defined by the ninert parameter. This way you can have inertia as a function of the band within which concludes the positioning.

By setting the dobiner = 0 parameter, the device manage a unique inertia value independently of direction of movement (forward or backward).

By setting the dobiner = 1 parameter, the device manage two inertia values for each band, one for the forward direction and another for the backward direction. This mode is applicable, for example, when you move the vertical axis.

For storing inertia, are used the iner01÷ iner08 parameters (in the event that dobiner = 0) or the iner01÷ iner16 parameters (if dobiner = 1):

| dobiner = 0 | dobiner = 1 | |

|---|---|---|

| iner01 | Inertia 1 band | Forward intertia 1 band |

| iner02 | Inertia 2 band | Backward intertia 1 band |

| iner03 | Inertia 3 band | Forward intertia 2 band |

| iner04 | Inertia 4 band | Backward intertia 2 band |

| iner05 | Inertia 5 band | Forward intertia 3 band |

| iner06 | Inertia 6 band | Backward intertia 3 band |

| iner07 | Inertia 7 band | Forward intertia 4 band |

| iner08 | Inertia 8 band | Backward intertia 4 band |

| iner09 | n.u. | Forward intertia 5 band |

| iner10 | n.u. | Backward intertia 5 band |

| iner11 | n.u. | Forward intertia 6 band |

| iner12 | n.u. | Backward intertia 6 band |

| iner13 | n.u. | Forward intertia 7 band |

| iner14 | n.u. | Backward intertia 7 band |

| iner15 | n.u. | Forward intertia 8 band |

| iner16 | n.u. | Backward intertia 8 band |

By definition, the forward inertia is used only forward in movements (forward output enabled) while, the backward inertia, is used only for backward movements (backward output enabled).

1.4.7 Managing Automatic recalculation Inertia

The calculation of inertias about the various bands can be done automatically by the device; at the end of each placement, the device quantify the value of inertia for use in subsequent placements that will end in the same band.

You can define a set of customizations related to automatic recalculation of inertia.

1.4.7.1 Inertmode

With the setting of this parameter is used to define when the device execute the recalculating of inertia; there are two methods:

-

The recalculation is executed only if the placement ends outside the tolerance range.

-

The recalculation is executed at the end of each placement, although it ended in or out of the tolerance range.

1.4.7.2 Toldly

-

Automatic recalculation of inertia is executed by OOPOS2 device when ended the activation delay tolerance (toldly), at the end of which the axis is considered definitely in stop.

1.4.7.3 Maxiner

-

If the value of the inertia recalculated diverges beyond a certain value from inertia in use, you can have an alert (st_erin = 1 state); this alert may in any case be disabled.

1.4.8 The preset search

The preset searchb is a procedure to synchronize the value of the posit parameter with the actual position of the axis. Consists to load a value in the counter (previously stored) at the time of acquisition of transducer zero pulse; you can execute the preset search with a transducer without the zero pulse, but you need an input (cam or sensor) by 'enabling zero-pulse transducer'.

Formerly to the preset search the counter acquired can have any value and the axis can be located anywhere. For execute the upload of preset quota, the axis you must direct to the “enabling zero-pulse transducer” input.

The initial direction of motion is defined by prsdir parameter:

prsdir = 0 the axis will start getting forward.

prsdir = 1 the axis will start getting backward.

| During the preset search the software the maxpos and minpos limits are disabled. |

|---|

The preset search start is given from the PRESET command.

If during the preset search is given again the PRESET command, the direction of motion of the axis is reversed, preserving the operation of the preset search direction.

It should be noted that the presets quota (prspos) must always be between the minimum and maximum quotas and after the load of the preset quota, the axis is automatically positioned to the preset quota.

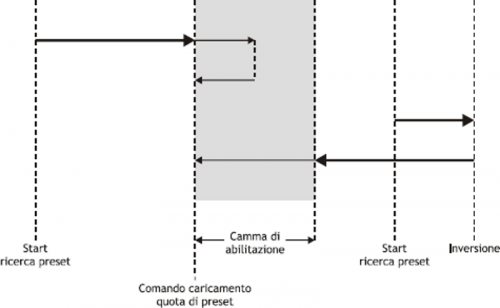

1.4.8.1 Mode 0: loading presets with moving procedure

| The zero pulse enable input has a hardware filter which delays the acquisition and so influence the precision of the loading. Axis speed should be low enough to allow the acquisition of the input. |

|---|

The axis towards to the sensor connected to the enable input zero pulse with a normal placement speed. The st_prson state reports that the preset procedure is in progress. When, during the path, the axis bump into the enabling zero-pulse transducer input, reverses the direction and takes slow speed.

To the disabling of enabling zero-pulse transducer input is loaded the preset quota on the counter (posit parameter).

The axis stop, the st_prson state is disabled and the st_prsok state is aenabled to signal the end of search. This State remains active until the starting of a new presets procedure. When the system is power up this state is always to zero (Picture 1).

| Picture1: preset load using the only enabling cam. |

|

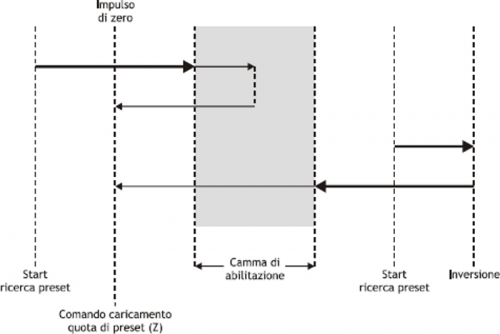

1.4.8.2 Mode 1: preset load with moving procedure

| The acquisition is execute on interrupt input then the speed of the axis is not determinative. However, you must verify that the zero pulse activation time is long enough to be captured by the card. |

|---|

The axis towards the sensor connected to input enabling zero-pulse with normal positioning speed. The st_prson state reports that the preset procedure is in progress. When, during the path, the axis mbump into the enabling zero pulse transducer input, reverses the direction and takes the slow speed.

To disable the zero pulse enable input is enabled the reading of the first zero-pulse provided by the transducer and at the time of the acquisition of this signal, is loaded the preset quota in the counter (posit parameter).

The axis stops, the st_prson state is disabled and the st_prsok state is enabled to signal the end of search. This state remains active until the starting of a new procedure of presets. When the system is power up this State is always zero (Picture 2).

| Picture 2: loading presets using cam and zero pulse enable transducer. |

|

1.4.8.3 Mode 2: loading with stopped axis

With this procedure the preset search is not enabled. The command to load the preset quota is provided by the activation of the zero pulse enable input and is enabled the st_prsok state.

-

If the input remains active the loading is continuous.

-

If the input is already active to the power on the first load is executed only after its disabled.

1.4.9 Delta count

| The command can be sent only if the axis is stopped, condition of st_still = 1. |

|---|

The device always shows the absolute position of the axis; to execute the incremental placements it is necessary to have a tool to subtract or add some value to the count (posit) without introducing errors. The change counter can be execute even with a direct writing to the new value in the posit parameter.

Wanting to steal 100 units of measure from the count you can:

Axis:posit = Axis:posit - 100

| The Changing of the value resolution (cntratio) or write to the posit variable, causes the reset of the remnants of the conversion. |

|---|

This operation introduces an error because it imposes the location “posit = -100”, when the axis could have an intermediate position between a unit of measurement and subsequent (example 100.3). This fraction (0.3) is lost and the repetition of these steps results in the accumulation of a considerable error.

The DELCNT command sum to the count an amount equal to the delta parameter without losing the fraction part of the position:

Axis:delta = -100

DELCNT Axis

The DELCNT command can be sent only with stationary axis (st_still=1)

1.4.9.1 Example

The reading of the position of the axis is of 2 units and is located at point A. To sum the count posit three units.

With instructions:

Axis:posit = Axis:posit + 2

the axis takes the new position B.

With instructions:

Axis:delta = 2

DELCNT Axis

It's reached the point C.

Note that with the first instructions the axis took a delta less than 3 units and then introduced an error.

If you need to send the succession of DELCNT commands, It is convenient to calculate the quantity to be summed and send at once the command; otherwise beware not to send subsequent commands without a read statement on device parameter.

1.4.9.2 Example

Axis:delta = 3 DELCNT Axis WAIT Axis:st_init Axis:delta = 40 DELCNT Axis

A writing of the type:

Axis:posit = 1000 Axis:delta = - 100 DELCNT Axis DELCNT Axis ...

Does not ensure that the posit value is 800, as you would expect from two consecutive subtraction, while it's possible is 900 for the overlap of the two commands. The writing becomes then:

Axisposit = 1000 Axis:delta = - 100 DELCNT Axis WAIT Axis:st_init DELCNT Axis WAIT Axis:st_init ...

1.4.9.3 REGON and REGOFF commands

With the OOPOS3 device address the movement outputs are for the exclusive use of the device; so they can't be used by other device or by the application.

The REGOFF command allows you to make available these resources, by disabling the update from the OOPOS3 device. This condition, verified by the st_regoff = 1 state, places the device in a pending state that still continues to update the position of the axis (acquired counting).

The REGON command restores normal conditions giving the device updating outputs.

| To avoid conflicts and malfunctions, must necessarily be active one device for each group of outputs of movement. |

|---|

In the applications that do not need to move the multiple axes, use of REGON/REGOFF controls allows you to use the same motion outputs saving hardware resources.

1.4.10 Moving

The procedures described here were allowed to complete the steps necessary to device hardware resource definition, electrical verification, of fundamental device parameters setting.

Now you can run simple movement of the axis.

-

Move the axis in a position whereby it can fulfill a certain area without meeting the quota limit.

-

Reset the count (posit = 0 parameter).

-

Set the placement quota (setpos parameter).

Axis:setpos = positioning quota(in Um between minpos and maxpos). -

tart positioning (START command).

START Axis -

To stop the positioning use the STOP command.

1.5 Special functions

1.5.1 QPS Positioning system (QEM POSITIONING SYSTEM)

| This system allows, If the resolution of the transducer allows it, adjust and check the position of the On/Off type with a resolution 10 times greater than the set. |

|---|

The introduction of inertia parameters (iner01 ÷ iner16), the tolerances (tolp and toln) and thickness tool (tool), is proposed with an addition digit, so you can introduce the data with an accuracy 10 times greater.

For a good operation of the QPS system, the cntratio parameter should be less than 40000; if the multiplicative coefficient is between 40001 and 399999 the influence of the last digit will decrease gradually up to cease completely when this coefficient is equal to 400000.

The QPS system is also introduced in the reading of the data described above.

1.5.1.1 Examples

| The examples are based on a system of positioning with millimetre precision. |

|---|

-

If a placement fee equal to 10 mm is normally inserted with the number 10, to introduce the same tolerance value (then with the QPS), you must enter the value 100.

-

A tolerance of 10 mm will be displayed with the number 100.

1.6 Commands and parameters table

1.6.1 Symbols used

The parameter name, state or command are is shown on the left side of the table.

R

Indicates if the parameter or state is retentive (upon initialization of the device maintains the previously defined state), or the state assumes upon initialization of the device.

If the device does not need to initialize the “R” field indicates the value that the parameter or state take to the power up of the card.

R = Retentive

0 = Upon initialization of the device the value is forced to zero.

1 = Upon initialization of the device the value is forced to one.

- = Upon initialization of the device is presented significant value.

D

Indicates the size of the parameter.

F = Flag

B = Byte

W = Word

L = Long

S = Single Float

1.6.1.1 Conditions

Describes all the conditions that must exist is considered correct or because the command is accepted.

In some cases, limit values are specified for the acceptance of the parameter: If are introduced any values outside the limits set, the data is however accepted; therefore appropriate controls of the application must be provided to ensure the proper functioning.

To execution of the command, all conditions must be met; otherwise the command is not sent.

A

Indicates the access mode.

R = Read.

W = Write.

RW = Read / Write.

1.6.2 Commands

The commands were ranked by decreasing priority. For example, in the case of contemporary STOP and START commands, is acquired first theSTOP command.

| Name | Conditions | Description |

|---|---|---|

| INIT | st_init = 0 | Initialization Initializing device command. If the device is not initialized, does not execute the axis calculations and then sits idle. To power on you can download all parameters in DPR; subsequently, with the INIT command the axis will be initialized, executing the calculations only once. Activates the st_init state. |

| START | st_init = 1 st_regoff = 0 st_still = 1 | Start Controls the positioning to setpos quota and setvel speed. |

| STOP | st_init = 1 st_regoff = 0 st_emrg = 0 | Stop Stops the current axis positioning. The stop of the axis follows the deceleration ramp in use. The axis remains in reaction to space. |

| CNTLOCK | st_init = 1 | Counter lock Blocks the acquisition of axis count even if the transducer continues to send signals. At this stage the possible displacement of the axis is not detected. Disables loading of presets quota on the count. Activates the st_cntlock state. |

| CNTUNLOCK | st_init = 1 | Counter unlock Unlock the axis count. Recovered read the signals sent by the transducer and the updating count. Disable the st_cntlock state. |

| CNTREV | st_init = 1 | Counter reverse Invert the phases of the transducer into the card. It's reversed the direction of the count (increase/decrease). Activates the st_cntrev state. |

| PRESET | st_init = 1 st_regoff = 0 | Preset Start search preset axis. Start search procedure with modes set with prsmode and prsdir parameters. If the preset search is already in execution, the command executes the reverse search. Activates the st_prson state and disable the st_prsok state |

| MANSFW | st_init = 1 st_regoff = 0 posit < maxpos | Manual slow forward Manual slow positioning forward. Activates the forward and slowdown outputs. |

| MANSBW | st_init = 1 st_regoff = 0 posit > minpos | Manual slow backward Manual slow positioning backward. Activates the backward and slowdown outputs. |

| MANFFW | st_init = 1 st_regoff = 0 posit < maxpos | Manual forward Manual positioning forward. Activates the forward output. |

| MANFBW | st_init = 1 st_regoff = 0 posit > minpos | Manual backward Manual positioning backward. Activates the backward output. |

| REGON | st_init = 1 | Regulation ON Enable adjustment and updating of movement outputs, and all the movement commands. Disable the st_regoff state. |

| REGOFF | st_init = 1 | Regulation OFF Disable adjustment and updating of movement outputs, and all the movement commands. Only the brake output continues to be updated. Activates the st_regoff state. |

| DELCNT | st_init = 1 st_still = 0 | Delta counter This command is accepted only if the axis is stopped; the counter (axis position) is modify by adding algebraically the value specified in the delta variable. |

1.6.3 Parameters

| Name | D | R | A | Conditions | Description |

|---|---|---|---|---|---|

| cntratio | L | R | R-W | No | Counter ratio Defines how the transducer pulses must be multiplied so that the acquisition of movements is expressed in the unit of measure desired. If setting 100000, the count variation is 1 bit for pulse transducer. Valid range: 347 ÷ 400000 |

| posit | L | R | R-W | st_init = ON | Actual position Is the value of the instantaneous position of the axis in units defined by the cntratio parameter. Value expressed in units of measurement (Um). Valid range: -999999 ÷ 999999 |

| minpos | L | R | R-W | No | Minimum position Defines the minimum quota to reach from the axis; the set value is considered as the lower limit for the introduction of quotas work. Value expressed in units of measurement (Um). Valid range: -999999 ÷ 999999 |

| maxpos | L | R | R-W | No | Maximum position Defines the maximum quota reached by the axis; the set value is to be considered also as an upper limit for the introduction of quotas of work. Value expressed in units of measurement (Um). Valid range: -999999 ÷ 999999 |

| slowpos | W | R | R-W | No | Slow position Is the distance from the positioning quota which is axtivates the slowdown output. Value expressed in units of measurement (Um). Valid range: 0 ÷ 9999 |

| tollp | W | R | R-W | No | Positive tolerance Is the positive tolerance limit allowed to positioning (maximum error for excess). It is expressed as Um/10 (QPS). Valid range: 0 ÷ 9999 |

| tolln | W | R | R-W | No | Negative tolerance Is the negative tolerance limit allowed to positioning (maximum error by defect). It is expressed as Um/10 (QPS). Valid range: 0 ÷ 9999 |

| tinv | W | R | R-W | No | Direction inversion delay Is used to avoid mechanical stress caused by too rapid direction changes movement. The input value is expressed in hundredths of a second. Valid range: 0 ÷ 999 |

| slowdly | W | R | R-W | No | Slow delay When positioning enters in the deceleration range, the output is disabled for a time determined by the slowpos parameter. The output of slowdown is activated with time slowpos/2 before the release of movement. It's expressed in hundredths of a second (s/100). Valid range: 0 ÷ 999 |

| tbrake | W | R | R-W | No | Brake time Is the time elapsing, to start positioning, between the brake release (depending on the breaktype parameter) and the activation of outputs of movement. It's expressed in hundredths of a second (s/100). Valid range: 0 ÷ 999 |

| overpos | W | R | R-W | No | Over position Overquota for backlash recovery and/or minimum delta of positioning. If set to zero does not run the backlasch recovery. Value expressed in units of measurement (Um). Valid range: 0 ÷ 9999 |

| bklashmode | B | R | R-W | No | Backslash mode Select the backlash type: 0=positioning without backlash recovery. 1=positioning with forward backlash recovery. 2=positioning with backward backlash recovery. 3=positioning with forward backlash recovery without slowdown. 4=positioning with backward backlash recovery without slowdown. If the parameter is out o allowedf limits, uses by default the mode 0. |

| ninert | B | R | R-W | No | Inertia number Is the number of the inertia bands in which dividing the axis. If you set the value zero, considering a single band. Valid range: 1 ÷ 8 |

| maxiner | W | R | R-W | No | Maximum inertia Is the maximum value change of inertia after each placement. If the calculated value exceeds this parameter, is indicated by the st_erin state. If the value is set to zero, the control is inhibited. It's expressed in Um/10 (QPS). Valid range: 0 ÷ 9999 |

| toldly | W | R | R-W | No | Tolerance delay Defines the time between the arrival of the axis in the tolerance range and the status report. The input value is expressed in hundredths of a second. Valid range: 0 ÷ 9999 |

| inertmode | B | R | R-W | No | Inertia mode selection Indicates the type of inertia recalculation performed by the device at the end of the placement: 0=recalculating inertias disabled. 1 = recalculating inertia only execute if the placement ends out of tolerance. 2=recalculation inertia executing at each positioning. |

| tool | L | R | R-W | No | Tool thickness Is the thickness value tool. This value, expressed in Um/10 (QPS), is added to the placement quota setpos when it's commanded START. The final quota of the axis will be then given by: setpos + tool Valid range: -999999 ÷ 999999 |

| setpos | L | R | R-W | No | Setted position Is the set quota of positioning. It's running from the START command. If it is changed during the placement, the axis is positioned at the previous quota. Value expressed in units of measurement (Um). Valid range: -999999 ÷ 999999 |

| iner01÷iner16 | W | R | R-W | No | Inertia 01 ÷ 16 value Are the 16 memories of inertia values. If the dobiner parameter is to 0, device only uses the first eight (iner01 ÷ iner08). It's expressed in Um/10 (QPS). |

| dobiner | B | R | R-W | No | Double inertia With this parameter you can choose to recalculate a unique inertia for all that has divided the axis or get two for every band range: one for each direction of the axis. 0=Inertia memory band equal for two directions. 1=Inertia memory band distinct for two directions. |

| enstol | B | R | R-W | No | Enable start in tolerance Enable start with axis in tolerance: 0 = START in tolerance disabled. At the START command the st_sttoll state is enabled and the axis stay to still. 1 = START in tolerance enabled. At the START command the axis execute a repositioning to the quota in use and the st_sttoll state is disabled. |

| prsmode | B | R | R-W | No | Preset mode Defines the type of preset search: 0 = For research enabling zero-pulse, the axis begins the movement, bump the enabling cam, reverses the direction and slow on falling edge on the cam signal, load the preset quota. 1 = For research of enabling zero-pulse, the axis begins thr movement, bump the enabling cam, reverses the direction and slowly acquires the first zero-pulse (after disabling the cam signal). 2 = Does not activate the search procedure presets with axis handling. The count is updated to the presets quota to the activation of the enabling zero-pulse. |

| prspos | L | R | R-W | No | Preset position Defines the value that is loaded on the counting with the preset search procedure. Value expressed in units of measurement (Um). Valid range: minpos ÷ maxpos |

| prsdir | B | R | R-W | No | Preset search direction Defines the direction of movement of the cam research axis zero pulse enable. 0=The axis is looking forward, before rapidly, then in slow. 1=The axis is looking back, first in rapidly, then slowly. 2= The axis is looking forward always slow. 3= The axis always searches backward in slow. |

| actiner | B | R | R | No | Actual inertia Indicates the inertia range in use. Valid range: 0 ÷ 7 |

| delta | L | R | R-W | No | Delta counter Use variable as an operand from the DELCNT command. Value expressed in units of measurement (Um). Valid range: -999999 ÷ 999999 |

| decpt | B | R | R-W | No | Decimal point Defines the accuracy with which you wish to set presets and view the counts in relation to axis. Valid range: 0 ÷ 3 |

| unitvel | B | R | R-W | No | Velocity unit Defines if time unit of speed is expressed in minutes or seconds. 0 = Um/min 1 = Um/sec |

| frq | L | - | R | No | Actual frequency Is the value of the instantaneous frequency of the axis, considering a phase of the encoder. Value expressed in Hz. |

| vel | L | - | R | No | Actual velocity Is the value of the instantaneous speed of the axis. The value is expressed in Um/s or Um/min depending on the unitvel parameter and also depends on the decpt parameter. |

| breaktype | B | R | R-W | No | Brake type It's the type of brake intervention logic output. 0 = L'uscita viene eccitata per la frenata. 1 = L'uscita, normalmente eccitata, viene diseccitata per la frenata. Lo stato st_brake segue lo stato elettrico dell'uscita. |

| slowtype | B | R | R-W | No | Slow type It's the calculation type of slowdown 0=fixed with slowpos parameter. 1=proportional to the speed. 2=proportional to the square of speed. |

| maxvel | L | R | R-W | NO | Maximum velocity Defines the maximum axis speed. The input value is per unit of time of the unitvel set speed. This parameter is used if slowtype = 0. |

| maxslow | W | R | R-W | No | Maximum slowdown Is the value of deceleration calculated at the maximum speed of the axis defined by the maxvel parameter. This parameter is used if slowtype = 0. Value expressed in units of measurement (Um). Valid range: 0 ÷ 9999 |

| minslow | W | R | R-W | No | Minimum slowdown Is the minimum value of slowdown which can be calculated. This parameter is used if slowtype = 0. Value expressed in units of measurement (Um). Valid range: 0 ÷ 9999 |

| exeslow | W | - | R | No | Execution slowdown If the slowtype parameter ¹ 0 indicates the value of deceleration calculated from the device depending on the speed of the axis. Value expressed in units of measurement (Um). |

1.6.4 States

| Name | D | R | A | Conditions | Description |

|---|---|---|---|---|---|

| st_init | F | - | R | No | Initialization Reporting of device initialized. 0 = Device is not initialized. 1 = Device initialized. |

| st_cntlock | F | R | R | No | Counter locked Counting signaling axis blocked. 0 = Axis count unlocked. 1 = Axis count blocked |

| st_cntrev | F | R | R | No | Counter reversed Report of inverted axis count. 0 = Axis count not inverted 1 = Axis count inverted. |

| st_movfwd | F | 0 | R | No | Forward movement Report activation of forward movement output. 0 = Forward output not enabled. 1 = Forward output enabled. |

| st_movbwd | F | 0 | R | No | Backward movement Report activation of backward movement output. 0 = Backward output not enabled. 1 = Backward output enabled. |

| st_movslow | F | 0 | R | No | Slowdown movement Report activation of slowdown output. 0 = Slowdown output not enabled. 1 = Slowdown output enabled. |

| st_toll | F | 0 | R | No | Tolerance Reporting of axis in tolerance in relation to the quota put running from the START command. Signaling axis in tolerance may be delayed through toldly parameter. 0 = Axis not in tolerance. 1 = Axis in tolerance. |

| st_brake | F | 0 | R | No | Brake Reporting brake output signals (for activation of brakes or axis locking devices). 0 = Brake output is not activated. 1 = Brake output activated. |

| st_movdir | F | 0 | R | No | Backward direction Indication of direction of movement. 0 = Forward 1 = Backward. |

| st_still | F | 1 | R | No | Still Reporting of still axis. 0 = Axis moving. 1 = Axis stopped. |

| st_erin | F | 0 | R | No | Inertia ricalculation error Report an error recalculating inertia. The indication is activate if the recalculation of the inertia provides a value greater than maxiner parameter. 0 = Correct recalculation inertia. 1 = Recalculating inertia with values greater than maxiner. |

| st_sttoll | F | 0 | R | No | Start in tolerance If active reports (with enstol parameter 1 1) that was given a movement command and the axis was already in tolerance quota of finish line. The state remains unchanged until the next movement command (START, MANSFW, MANFFW, MANSBW, MANFBW). 0 = Start with axis out of tolerance. 1 = Start with axis in tolerance. |

| st_prsok | F | 0 | R | No | Preset ok Axis preset search reporting was successfully executed. 0 = Search for preset not yet completed or not executed. 1 = RPreset search was successfully executed. |

| st_prson | F | 0 | R | No | Preset Reporting of preset research axis ongoing. 0 = Preset search not in progress. 1 = Preset search in progress. |

| st_regoff | F | 0 | R | No | Regulation off Reports the status of disable outputs and positioning commands. 0 = Outputs of movement enabled. 1 = Outputs of movement disabled. |

1.7 Limitations

No limitation.

1.8 Application example

1.8.1 Configuration file

;************************************************************************************* ; Module name: Ex_Oopos.CNF Project: Ex_OOPOS2 ; Autor: QEM srl Date: 01/05/99 ; System: QMove1 / QCL3 Library: 1LIB3B04 ; Functionality: Example of OOPOS2 management Release: 0 ;-------------------------------------- Note ----------------------------------------- ; [1] - Sample application to use the OOPOS 2 device ;************************************************************************************* ;------------------------------------------------------------------------------------- ; Constant definition ;------------------------------------------------------------------------------------- CONST ;------------------------------------------------------------------------------------- ; Variable Definition SYSTEM ;------------------------------------------------------------------------------------- SYSTEM slQuotaPos L ;Variable for placement quota ;------------------------------------------------------------------------------------- ; Variable Definition GLOBAL ;------------------------------------------------------------------------------------- GLOBAL gfMovMan F ;Flag signalling manual movements in ;progress gfMovAuto F ;Flag signalling automatic movements in ;progress ;------------------------------------------------------------------------------------- ; Variable Definition TIMER ;------------------------------------------------------------------------------------- TIMER ;------------------------------------------------------------------------------------- ; Definition DATAGROUP ;------------------------------------------------------------------------------------- ;DATAGROUP ;------------------------------------------------------------------------------------- ; Bus Configuration ;------------------------------------------------------------------------------------- BUS 1 1CPUB 02 2 1MIXA 00 3 . 4 . ;------------------------------------------------------------------------------------- ; Variable Definition INPUT ;------------------------------------------------------------------------------------- INPUT ifAvMan F 2.INP01 ;Forward manual input ifInMan F 2.INP02 ;Backward manual input ifStart F 2.INP03 ;START axis input ifStop F 2.INP04 ;STOP axis input ;------------------------------------------------------------------------------------- ; Variable Definition OUTPUT ;------------------------------------------------------------------------------------- OUTPUT ofToll F 2.OUT04 ;Output axis tolerance ;------------------------------------------------------------------------------------- ; Internal device declaration ;------------------------------------------------------------------------------------- INTDEVICE ;Name Type TCamp Counter Inter AbilZero OutAva OutInd OutDir OutMov Axis OOPOS2 0004 2.CNT01 1 2.INP01 2.OUT01 2.OUT02 X.X X.X OutRal OutFre 2.OUT03 X.X END

1.8.2 OOPOS2 management

;------------------------------------------------------------------------------------- ; File Name: TASK_00.MOD ; Project: EX_OOPOS2 ; Description: Positioning Control ;------------------------------------------------------------------------------------- ;------------------------------------------------------------------------------------- ; Initialization work Axis ;------------------------------------------------------------------------------------- Axis:cntratio = 100000 ;Encoder resolution = Space in 1 round ;encoder(Um) / pulses round encoder Axis:maxpos = 999999 ;Maximum quota Axis:minpos = -999999 ;Minimum quota Axis:slowpos = 100 ;Slowdown quota Axis:tollp = 10 ;Positive tolerance Axis:tolln = 50 ;Negative tolerance Axis:tinv = 50 ;Inversion time Axis:slowdly = 50 ;Slowdown time Axis:tbrake = 30 ;Brake reaction time Axis:overpos = 0 ;Overquota for backlash recovery Axis:bklashmode = 0 ;Backlash recovery type Axis:ninert = 1 ;Inertia bands number Axis:maxiner = 100 ;Maximum inertia recalculated Axis:toldly = 50 ;Time delay tolerance reporting Axis:inertmode = 1 ;Recalculation inertia type Axis:tool = 0 ;Blade thickness Axis:dobiner = 0 ;Enabling split inertia ;(forward and backward) Axis:enstol = 0 ;Enable START with the axis ;tolerance Axis:prsmode = 0 ;Search type of presets Axis:prspos = 0 ;Preset quota Axis:prsdir = 0 ;Preset search direction Axis:decpt = 1 ;Decimal digits Axis:unitvel = 1 ;Time unit of speed Axis:breaktype = 0 ;Brake intervention logic Axis:slowtype = 0 ;Slowdown calculation type Axis:maxvel = 1000 ;Maximum speed Axis:maxslow = 8 ;Calculated maximum slowdown Axis:minslow = 80 ;Calculated minimum slowdown INIT Axis ;Initializes the device WAIT Axis:st_init ;Wait until the device is initialized CNTUNLOCK Axis ;Unlock count WAIT NOT Axis:st_cntlock ;Wait until the count is unlocked CNTDIR Axis ;Sets the direction of the count WAIT NOT Axis:st_cntrev ;Wait until it has the sense of ;count REGON Axis ;Enable the regulation WAIT NOT Axis:st_regoff ;Wait for enabling regulation IF (slQuotaPos EQ 0) ;In the event that the placement quota ;of the axis is zero slQuotaPos = 2000 ;Sets a quota of positioning ENDIF ;------------------------------------------------------------------------------------- ; Positioning tasks ; --------------------------------- used variables ---------------------------------- ; slQuotaPos: Adjustable variable that represents the quota of axis positioning ; --------------------------------- used flags -------------------------------------- ; gfMovMan: Manual movement in progress ; gfMovAuto: Automatic movement in progress ;------------------------------------------------------------------------------------- MAIN: ;------------------------------------------------------------------------------------- ; Managing outputs ;------------------------------------------------------------------------------------- ofToll = Axis:st_toll ;Sets out of tolerance as the ;tolerance state ;------------------------------------------------------------------------------------- ; Managing automatic movements ;------------------------------------------------------------------------------------- IF ifStart ;Waits for the START input IF NOT gfMovMan ;Check that there are no movements ;manuals IF Axis:st_still ;Check that the axis is still Axis:setpos = slQuotaPos ;Sets the placement quota START Axis ;Execute the start of axis gfMovAuto = 1 ;Automatic movement in progress reports ENDIF ENDIF ENDIF IF ifStop ;Waits for the STOP input IF NOT Axis:st_still ;Check that the axis ISN'T still STOP Axis ;Execute the stop of axis ENDIF ENDIF IF gfMovAuto ;Controls automatic reporting ;in progress IF Axis:st_still ;Check that the axis is still gfMovAuto = 0 ;Reset status of Automatic movement ENDIF ENDIF ;------------------------------------------------------------------------------------- ; Manual movements management ;------------------------------------------------------------------------------------- IF ifAvMan ;Awaiting the input of manual operation IF NOT (gfMovAuto OR gfMovMan) ;Check that there are no movements ;automatics or manuals IF Axis:st_still ;Check that the axis is still MANFFW Axis ;Forward axis in manual gfMovMan = 1 ;Manual movement in progress reports ENDIF ENDIF ENDIF IF ifInMan ;Awaiting the manual movement input IF NOT (gfMovAuto OR gfMovMan) ;Check that there are no movements ;automatics or manuals IF Axis:st_still ;Check that the axis is still MANFBW Axis ;Forward axis in manual gfMovMan = 1 ;Manual movement in progress reports ENDIF ENDIF ENDIF IF gfMovMan ;If the axis moves in manual IF NOT (ifAvMan OR ifInMan) ;If the forward and backward inputs ;manual is OFF STOP Axis ;Stop the axis gfMovMan = 0 ;Remove the reporting of axis ;in manuale movement ENDIF ENDIF ;------------------------------------------------------------------------------------- ; Final operations ;------------------------------------------------------------------------------------- WAIT 1 JUMP MAIN END