P1R11FE30 - 001 : User manual

Informations

Release

This document is fully valid, except for errors or omissions.

| Release | Description | Date |

|---|---|---|

| 1.0 | New manual. | 06/11/13 |

Specifications

All rights reserved on this manual. No part of this document can be copied or reproduced in any form without prior written authorisation .

QEM does not insure or guarantee its contents and explicitly declines all liability related to the guarantee of its suitability for any purpose. The information provided in this document can be changed without notice. QEM shall not be held liable for any error that may appear in this document.

Registered Trademarks:

-

QEM® is a registered trademark.

-

Microsoft® and MS-DOS® are registered trademarks and Windows® is a trademark of Microsoft Corporation.

Description

The P1R11FE30 - 001 application, installed on the Qmove J1-R11-FE30, hardware is designed to control a cookies dispensing machine with 4 axes. The salient features of the P1R11FE30 - 001 are described below.

The manual will distinguish between standard characteristics and optional. characteristics.

Overview of the Characteristics

-

Axes MMB, MMC, MCB controlled by PID on space (brushless motors with servo drives or asynchronous motors with vector inverters).

-

Axis MT for the conveyor. Only encoder simulation signal is provided.

-

Homing functions for axes MMB, MMC, MCB.

-

Select the language

-

Modbus communication with ESA hmi panel.

-

Diagnostics of the inputs and the outputs.

-

Messagges for active faults, to assist troubleshooting.

-

Help Messagges.

-

Backup and restore of the data on non volativle memory (FLASH EPROM).

HMI

Standard Codes

The standard codes used throughout the operator interface:

1. Values in Yellow can be modified by the operator.

Touch the value and use the keypad to enter a setting, followed by  to confirm.

to confirm.

2. Some parameters offer selection by multiple choice. To select a setting, press

Standard Toolbar

On the top of the display, a standard toolbar shows this informations:

-

Machine state

-

Page name

-

Date and hour

Machine states

| State | Icon | Description |

|---|---|---|

| INITIALIZATION |  | Machine power up. Waiting for loading default datas. |

| HOMING |  | Machine in homing state. |

| MANUAL |  | Machine in manual state. |

| SETUP |  | Machine in setup, calibration or pid tuning state. |

| PROGRAMMATION |  | Machine in program edit state. |

| AUTO OFF |  | Machine in automatic state. Automatic cycle off. |

| AUTO ON |  | Machine in automatic state. Automatic cycle on. |

| ALARM |  | Machine in alarm state. |

Start Page

The start page shows the customer logo and provides the following functions:

| Button | Icon | Description |

|---|---|---|

| NEXT |  | Press on the button to open the next page. |

Main Menu

This page allows the operator to choose the section he wants to display:

| Button | Icon | Description |

|---|---|---|

| MAIN PAGE |  | Press on the button to open the main page. |

| PROGAMMATION |  | Press on the button to open the program edit page. |

| MACHINE SETUP |  | Press on the button to open the machine setup section. |

| ANALOG OUTS CAL |  | Press on the button to open the analog outputs calibration section. |

| PID TUNING |  | Press on the button to open the pid tuning section. |

| MAIN PAGE |  | Press on the button to open the I/O diagnostics section. |

Diagnostics

This page swows the state of all digital and analogic I/O

| Button | Icon | Description |

|---|---|---|

| EXIT |  | Press on the button to return to MAIN MENU page. |

Alarms

From any page that have the standard toolbar and if the machine is in ALARM state, if pressed  icon, will display this page:

icon, will display this page:

All alarms will be reset by pressing  .

.

Alarm list

| Alarm | cause | Solution |

| Emergency / Auxiliary off | manual emergency - input I05 = OFF | Check emergency button. |

| Fault MMB drive | input I01 = ON | Check driver state. |

| Fault MMC drive | input I02 = ON | |

| Fault MCB drive | input I03 = ON | |

| Encoder fault MMB motor | Encoder/Resolver doesn't work correctly. | Check the hw or the wirings. |

| Encoder fault MMC motor | ||

| Encoder fault MCB motor | ||

| Follerr error MMB axis | Axis MMB over the MAX FOLLOW ERROR allowed | Check the parametrisation or errors in the drive. |

| Follerr error MMC axis | Axis MMC over the MAX FOLLOW ERROR allowed | |

| Follerr error MCB axis | Axis MCB over the MAX FOLLOW ERROR allowed | |

| Cam error MMB motor | Axis has an error in cam execution. par1 = error code par2 = Error value | Check program datas. |

| Cam error MMC motor | ||

| Cam error MCB motor | ||

| Master speed too high | Conveyor speed too highto execute cam | Reduce master speed. |

By pressing  it displays hystoric alarm page.

it displays hystoric alarm page.

Hystoric alarm page

The alarm hystoric archive can contains at max 200 registrations. It's a FIFO type archive, so as soon as an alarm occurs with the historic already full, you will lose the oldest in the list.

It's important that the date and time are set correctly in setup, to allow a diagnostic alarm occurred more quickly and accurately as possible.

: slides back the pages of historical alarms;

: slides back the pages of historical alarms;

: moves along the pages of historical alarms;

: moves along the pages of historical alarms;

: back to ALARM page;

: back to ALARM page;

: keep pressed for 3 seconds to reset the archive.

: keep pressed for 3 seconds to reset the archive.

Setup

Machine Setup

This page allows the operator to choose the setup section he wants to display:

| Button | Icon | Description |

|---|---|---|

| CONVEYOR |  | Press on the button to select MT axis setup. |

| MMB MOTOR |  | Press on the button to select MMB axis setup. |

| MCB MOTOR |  | Press on the button to select MCB axis setup. |

| MMC MOTOR |  | Press on the button to select MMC axis setup. |

At the bottom of the page date and hour can be set.

| Button | Icon | Description |

|---|---|---|

| EXIT |  | Press on the button to return to MAIN MENU page. |

Conveyor Setup

| Name | Unit measure | Default | Range | Description |

|---|---|---|---|---|

| PULSE | imp | 1000 | 0 ÷ 99999 | Indicates the pulses multiplied by 4 provided by the slave encoder to obtain the space set in the measure parameter. This parameter is used for the calculation of the axis resolution with the formula: Resolution = measure* 4 / pulse The resolution must have a value between 0.00374 and 4.00000. |

| MEASURE | imp | 1000 | 0 ÷ 99999 | Indicates the space, in unit of measurement, covered by the axis to obtain the encoder pulses set in the pulse parameter. This parameter is used for the calculation of the axis resolution with the formula: Resolution = measure* 4 / pulse The resolution must have a value between 0.00374 and 4.00000. |

| UM DECPT | - | 1 | 0 ÷ 2 | Decimal numbers for axis quotas. |

| Button | Icon | Description |

|---|---|---|

| COPY |  | Press on the button to copy the MT resolution to the other slave axis. |

| EXIT |  | Press on the button to return to MAIN MENU page. |

MMB/MCB/MMC Setup

| Name | Unit measure | Default | Range | Description |

|---|---|---|---|---|

| PULSE | imp | 4000 | 0 ÷ 99999 | Indicates the pulses multiplied by 4 provided by the slave encoder to obtain the space set in the measure parameter. This parameter is used for the calculation of the axis resolution with the formula: Resolution = measure* 4 / pulse The resolution must have a value between 0.00374 and 4.00000. |

| MEASURE | mm | 1000 | 0 ÷ 99999 | Indicates the space, in unit of measurement, covered by the axis to obtain the encoder pulses set in the pulse parameter. This parameter is used for the calculation of the axis resolution with the formula: Resolution = measure* 4 / pulse The resolution must have a value between 0.00374 and 4.00000. |

| MAXPOS | mm | 99999.9 | 0 ÷ 99999.9 | Maximum axis limit. |

| MINPOS | mm | -99999.9 | 0 ÷ -99999.9 | Minimum axis limit. |

| UNITVEL | - | 0 | 0 ÷ 1 | Speed visualization mode. 0: speed in UM/min 1: seed in UM/sec |

| UM DECPT | - | 1 | 0 ÷ 2 | Decimal numbers for axis quotas. |

| MAXVEL | mm/min | 25000 | 0 ÷ 9999999 | Maximum axis speed. It can be found in calibration axis section. |

| TACC | s | 0.5 | 0 ÷ 999 | Time to take axis from zero to maximum speed. |

| TDEC | s | 0.5 | 0 ÷ 999 | Time to take axis from maximum speed to zero. |

| PRSMODE | - | 0 | 0 ÷ 1 | Homing mode. 0: Axis uses only Enable Switch Zero 1: Axis uses Enable Switch Zero and then Z encoder phase. |

| PRSPOS | mm | 0 | -99999 ÷ 99999 | Quota forced in axis position at the end of homing procedure. |

| PRSVEL | mm/min | 2500 | 0 ÷ 99999 | Axis speed during homing procedure. |

| SPRSVEL | mm/min | 250 | 0 ÷ 99999 | Axis speed during homing procedure. Used after move inversion. |

| PRSDIR | - | 1 | 0 ÷ 1 | Homing direction. 0: Axis starts homing forward 1: Axis starts homing backward. |

| Button | Icon | Description |

|---|---|---|

| EXIT |  | Press on the button to return to MAIN MENU page. |

Analog Outs Calibration

This page allows the operator to choose the axis calibration section he wants to display:

| Button | Icon | Description |

|---|---|---|

| MMB MOTOR |  | Press on the button to select MMB axis calibration. |

| MCB MOTOR |  | Press on the button to select MCB axis calibration. |

| MMC MOTOR |  | Press on the button to select MMC axis calibration. |

| Button | Icon | Description |

|---|---|---|

| EXIT |  | Press on the button to return to MAIN MENU page. |

MMB/MCB/MMC Calibration

The calibration section is used to find the offset of the axis and its maximum speed.

| Parameter Name | Unit measure | Default | Range | Description |

|---|---|---|---|---|

| OFFSET | bits | 0 | -999999 ÷ 999999 | Voltage value added to the Analog Axis Out to cancel the offset tension of the motor. |

| POSITION | mm/bits | - | - | Actual axis position. Display both in UM and in encoder bits. Press  to reset values. to reset values. |

To find OFFSET value:

| To find OFFSET value | |

|---|---|

| 1 | Press  to activate calibration. to activate calibration. |

| 2 | Insert value 0 (zero) in VOLTAGE OUTPUT parameter. |

| 3 | Increase or decrease OFFSET parameter till POSITION will be almost fixed (or move very slowly). |

| 4 | Press  to deactivate calibration. to deactivate calibration. |

| Parameter Name | Unit measure | Default | Range | Description |

|---|---|---|---|---|

| VOLTAGE OUTPUT | V | 0.0 | -10.0 ÷ 10.0 | Output voltage, in V/10, exit from C1-R11 pins. |

| VELOCITY | UM/'/Hz | - | - | Actual axis speed. Display both in UM and in hertz. |

| MAX VELOCITY | UM/' | 25000 | 0 ÷ 9999999 | Axis speed corresponding to 10V of the analog output. |

| Counter and direction verifying: | |

|---|---|

| with analog voltage over 0 (zero) the axis has to move to positive direction. | |

| 1 | Press  to activate calibration. to activate calibration. |

| 2 | Insert a positive value in VOLTAGE OUTPUT. |

| 3 | Check if POSITION parameter increases. |

| 4 | Press  to deactivate calibration: axis stops WITHOUT ramp. to deactivate calibration: axis stops WITHOUT ramp. |

| 5 | PAY ATTENTION Invert the rotation sense of the motor on the proper pins of C1-R11 (PHA and PHB) if the direction is incorrect. |

| Maximum speed: | |

|---|---|

| find the speed corresponding to 10V of the analog output. | |

| 1 | Press  to activate calibration. to activate calibration. |

| 2 | Insert a positive value in VOLTAGE OUTPUT (if possible close to 10V). |

| 3 | Read the value display in VELOCITY. |

| 4 | calculate the value of MAX VELOCITY parameter with: $ \text{MAX VELOCITY} = \dfrac{10\cdot \text{VELOCITY}}{\text{VOLTAGE OUTPUT}} $ |

| 5 | Press  to deactivate calibration: axis stops WITHOUT ramp. to deactivate calibration: axis stops WITHOUT ramp. |

| 6 | Insert calculated value in MAX VELOCITY. |

| Button | Icon | Description |

|---|---|---|

| EXIT |  | Press on the button to return to MAIN MENU page. |

PID Tuning

This page allows the operator to choose the axis tuning section he wants to display:

| Button | Icon | Description |

|---|---|---|

| MMB MOTOR |  | Press on the button to select MMB axis tuning. |

| MCB MOTOR |  | Press on the button to select MCB axis tuning. |

| MMC MOTOR |  | Press on the button to select MMC axis tuning. |

| Button | Icon | Description |

|---|---|---|

| EXIT |  | Press on the button to return to MAIN MENU page. |

MMB/MCB/MMC PID tuning

The PID tuning section is used to find the PID parameters of the axis.

| Parameter Name | Unit measure | Default | Range | Description |

|---|---|---|---|---|

| ACTUAL POS | Um | - | - | Actual position of the axis. |

| VEL | Um | - | - | Actual speed of the axis. |

| POSITION 1 | Um | 0.0 | -99999 ÷ 99999 | Target position when START POS 1 button is pressed. |

| POSITION 2 | Um | 100.0 | -99999 ÷ 99999 | Target position when START POS 2 button is pressed. |

| TEST VEL | Um/' | 0 | - | Speed in positioning mode. |

| ACC. TIME | s | 0.50 | - | Acceleration time in postioning mode. |

| DEC. TIME | s | 0.50 | - | Deceleration time in postioning mode. |

| FEEDFORWARD | % | 100.0 | 0.0 ÷ 200.0 | It's the percentage factor, multiplied par speed value, that generate the FF contribute of analog output voltage. |

| PROP. GAIN | - | 0 | 0 ÷ 9999 | It's the factor, multiplied par following error value, that generate the P contribute of analog output voltage. |

| INTEGRAL TIME | s | 0.000 | 0.000 ÷ 9.999 | It's the time factor that integrate the following error. This integration generates the I contribute of analog output voltage. |

| MAX FOLLOW ERR | bit | 9999 | 0.0 ÷ 999999 | Max accettable error between real and virtual axis posixion. |

| FOLLOW ERROR | bit | - | - | Actual following error. |

Operator can execute following operations after inserting these parameters in the other setup sections:

-

MEASURE/PULSE: set correct axis resolution.

-

MAXPOS: insert a big positive value (Es.: 9999 mm)

-

MINPOS: insert a big negative value (Es.: - 9999 mm)

To perform any of the settings described above, the following conditions must be met:

![]() Make sure that the emergency button to remove power to the motors so as to be in a safe condition in the event that the machine should move in an uncontrolled way.

Make sure that the emergency button to remove power to the motors so as to be in a safe condition in the event that the machine should move in an uncontrolled way.

Reset the machine from possible emergency conditions by resetting the alarms.

Reset the machine from possible emergency conditions by resetting the alarms.

| PID parameters: | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| parameters are: FEEDFORWARD, PROP. GAIN and INTEGRAL TIME. After performing the above steps correctly, continue with: | ||||||||||||||

| 1 | Insert value 100.0% in FEEDFORWARD parameter. | |||||||||||||

| 2 | Insert minimum value (1) in PROP. GAIN parameter. | |||||||||||||

| 3 | If FOLLOW ERR is different from 0 (zero), you will see a movement of the axis to reduce that value. | |||||||||||||

| 4 | Insert a value in POSITION 1 and POSITION 2 parameters and a value in TEST VEL parameter (minus of MAX VELOCITY) parameter. | |||||||||||||

| 5 | Press START POS 1 button to move axis to target quota POSITION 1 or START POS 2 button to target quota POSITION 2. | |||||||||||||

| 6 | During these movements it's possible to check FOLLOW ERROR value and set FEEDFORWARD and PROP. GAIN tring to decrease the error as more as possible. The criteria to be followed are:

|

|||||||||||||

| 7 | ||||||||||||||

| Button | Icon | Description |

|---|---|---|

| EXIT |  | Press on the button to return to MAIN MENU page. |

Main Page

This page shows:

-

POSITION : can be read actual position of all 4 axis;

-

SPEED: can be read the actual master (conveyor) speed. Between square the calculated max advice speed;

-

LAST ALARM: on a red back it can be read the last alarm (if the machine state is ALARM);

-

CAM STATUS: STOP or EXEC

-

HOMING STATUS: NOT OK or OK if done.

| Button | Icon | Description |

|---|---|---|

| START QUOTAS |  | Press on the button to move MMB, MCB and MMC axis to homing quota (beginning of the automatic cycle). |

| EXIT |  | Press on the button to return to MAIN MENU page. |

Edit Program

| Parameter Name | Unit measure | Default | Range | Description |

|---|---|---|---|---|

| MASTER load | bit | - | - | Portion of the master cam used to load cookies with MMB and MCB motors. |

| MASTER push | bit | - | - | Portion of the master cam used to take cookies on the conveyor with MMC motor. |

| MASTER rise | bit | - | - | Portion of the master cam used to take MMB motor to the upper position. |

| MMB motor Sp. acc./dec. | bit | - | - | Master space to accelerate and decelerate MMB motor during load phase. |

| MMB motor move | Um | - | - | Space from MMB upper position to the level of conveyor. |

| MCB motor Sp. acc./dec. | bit | - | - | Master space to accelerate and decelerate MCB motor during load phase. |

| MCB motor N. cookies | bit | - | - | Number of cookies for each packet. |

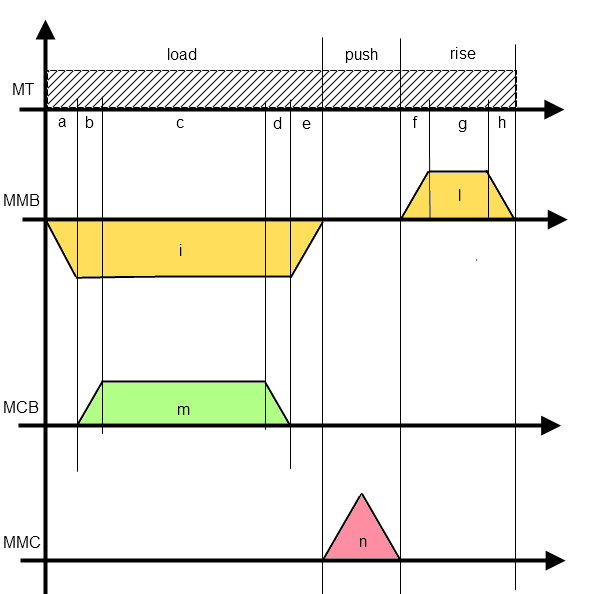

Example:

VERY IMPORTANT : load + push + rise have to be ALWAYS equal to 61440 bits (total master cam)

VERY IMPORTANT : load + rise have to by a multiple of 7680 (master space for every row)

| Name | Unit measure | Description |

|---|---|---|

| a / e / f / h | bit | Parameter MMB Sp. acc./dec. |

| b / d | bit | Parameter MCB Sp. acc./dec. |

| c | bit | Calculated master space for loading cookies. |

| g | bit | Calculated master space for rising movement of MMB motor. |

| i / l | bit | Parameter MMB move. These area are equal. Rising movement will be faster. |

| m | bit | MCB motor space calculation N. cookies x MCB motor turn (setup parameter MEASURE). |

| n | bit | MMC motor turn (setup parameter MEASURE). |

During the editing a red label on the top of the display inform the operator about the state of the program:

| Message | Description |

|---|---|

| PROGRAM OK ! | Program edited has no error. |

| MASTER SPACE SUM ERR | Sum of master spaces (load, push, rise) is not 61440. |

| MASTER SPACE = 0 | Any of master spaces (load, push, rise) is 0. |

| MMB DATA = 0 | Any of MMB datas (Sp. acc/dec, move) is 0. |

| MCB DATA = 00 | Any of MCB datas (Sp. acc/dec, N. cookies) is 0. |

| LOAD SP < MMB RAMPS | Load master space is minus than the MMB Sp acc/dec spaces. |

| LOAD SP < MCB RAMPS | Load master space is minus than the MCB Sp acc/dec spaces. |

| ERR LOAD+RISE SPACE | Sum of master spaces (load, rise) is not multiple of 7680. |